When you are first starting out as a 3D creator, you want to be able to experiment with as many different materials and mediums as you can.

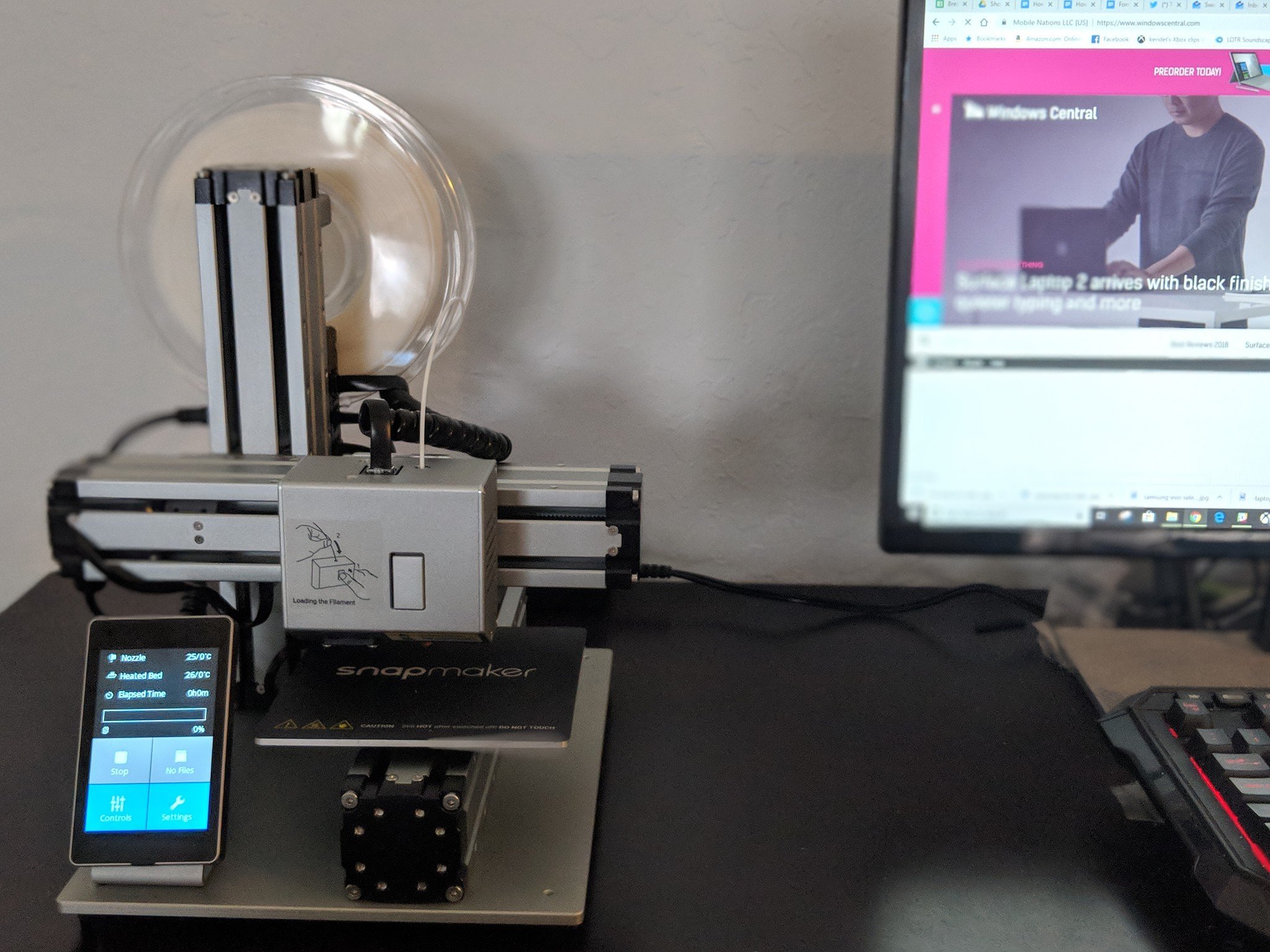

The Snapmaker 3-in-1 is the perfect machine to find your maker groove. With its three different configurations out of the box, it can be anything you want it to be, giving you the freedom to create anything and everything you can.

What you'll love about Snapmaker 3-in-1

The unique selling point of the Snapmaker is its modular design. Not only does it come with three separate tool heads, but the very structure itself is modular. Although Snapmaker has yet to sell the extensions, it is creating longer and shorter pieces to increase the size of your printer. One picture I saw showed a giant frame for using with the laser cutting module, allowing you to engrave far larger objects than you can with the stock machine.

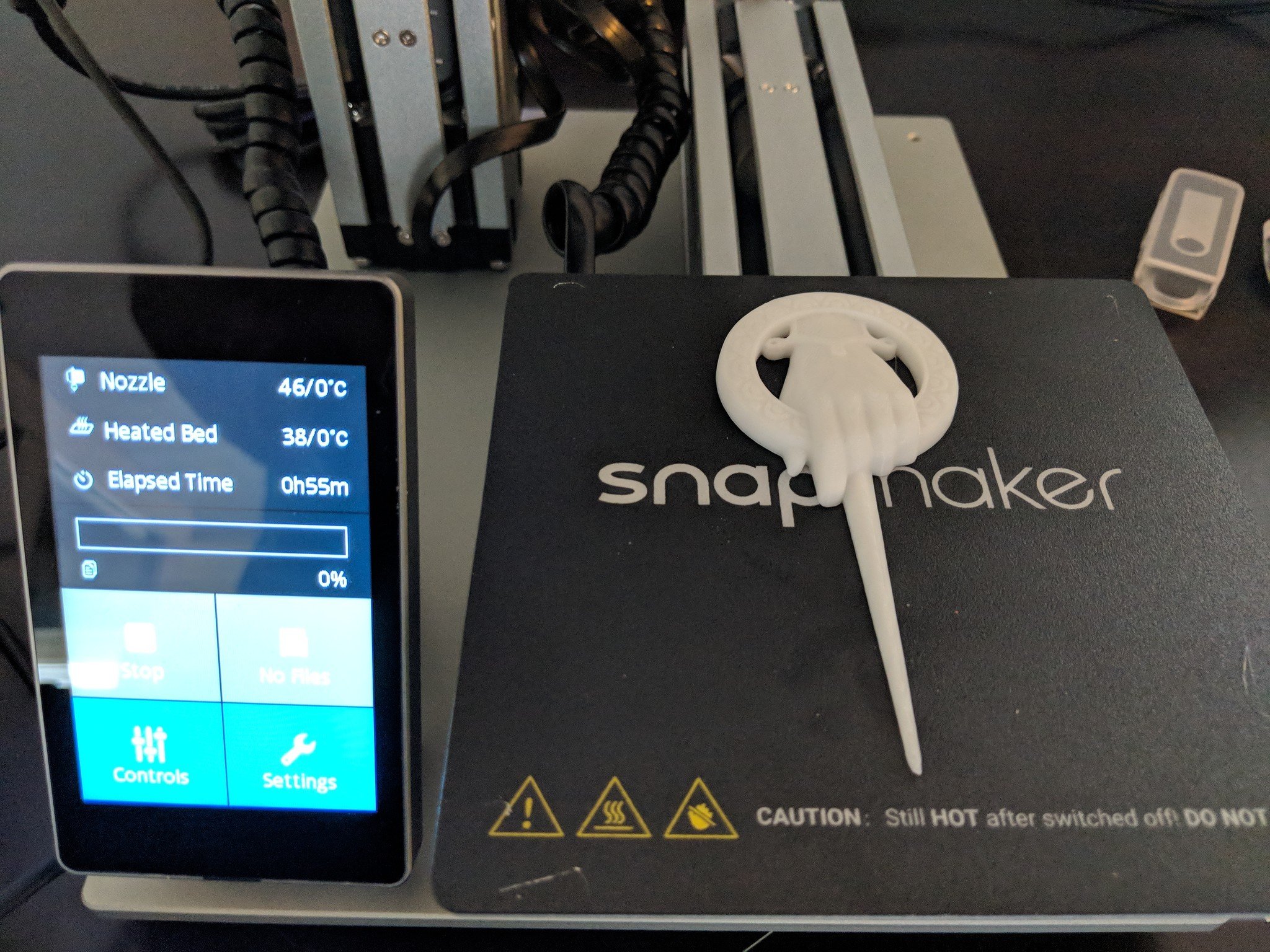

I was pleasantly surprised at how good the 3D printing module is on the Snapmaker. Every print I tried came out almost perfect every time and the software was simple to use. Snapmaker has gone to great strides to make sure the printer is open to everyone so it uses the standard 1.75-mm filament and has a heated bed to allow for various types of plastic. While the roll is situated somewhat clumsily in the back, a user has already created a filament guide to fix the issue and Snapmaker has said it is working on a fix.

The Snapmaker 3-in-1 is the perfect machine to find your 3D maker groove.

The company also told me it is looking at adding a cooling fan for the parts as they print though, though when I printed a Benchy — a model designed to check how well your printer prints — I could find nothing wrong with it except a little overhang.

Snapmaker even has an enclosure you can pick up for $149 that is beautiful to look at. The construction matches the printer, and the orange tinted windows can protect your eyes from the laser while it is running, as well as keep your printer at the correct temperature for printing Acrylonitrile Butadiene Styrene (ABS). ABS plastic is a strong, heat-resistant filament that needs a constant temperature to print.

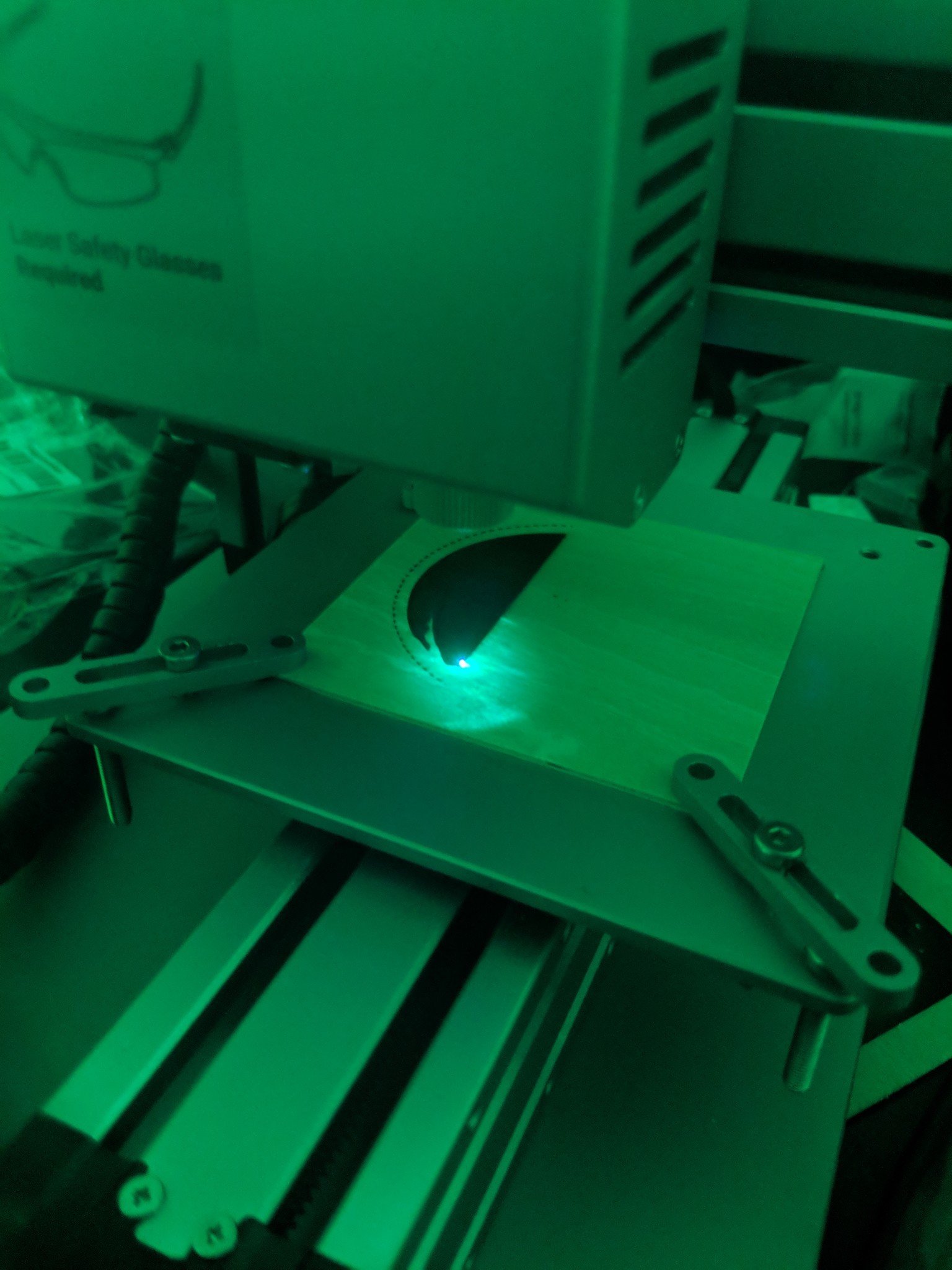

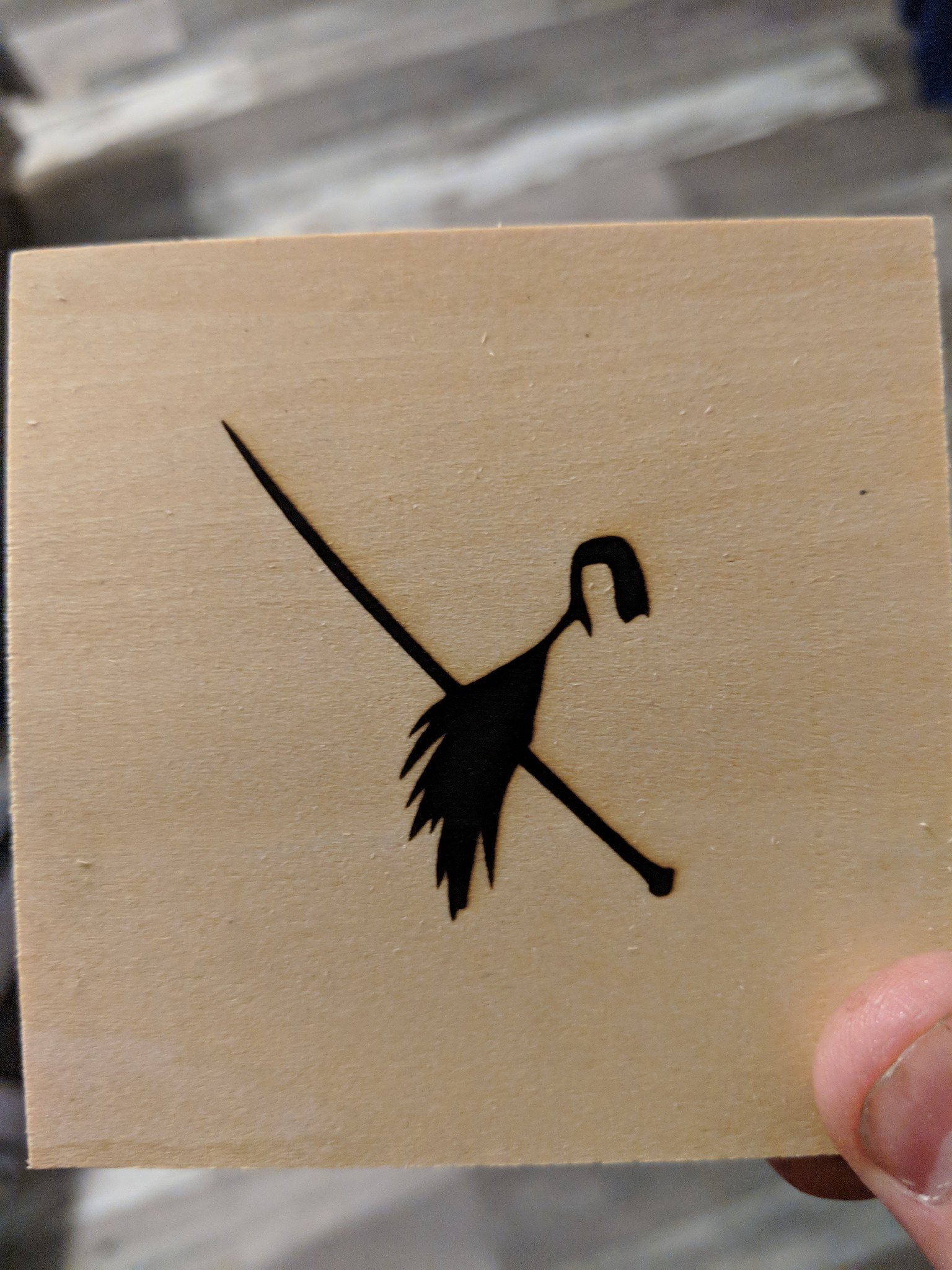

The laser module is both the best and worse thing on the Snapmaker 3-in-1. I was excited to try it out and set to work burning as many things as I could. The Snapmaker comes with some wooden squares to start you off and once I read the instructions correctly, I was converting pictures into charred etchings all day. I tried as many different materials as could on the laser etcher with varying degrees of success. Wood worked very well, as did colored plastics. However, clear acrylic didn't work unless I painted the top surface and washed it off. Leather worked really well, and even denim looked good, though it smelled terrible.

All the latest news, reviews, and guides for Windows and Xbox diehards.

The milling part of the Snapmaker is perhaps the most complicated. It comes with two separate milling bits that give different finishes and you can order new ones cheaply from the Snapmaker store. If you just want to carve a 2D shape, it is as easy as the laser etcher; just set the SVG image you want, center the machine, and it will cut your image into the wood, or in my case, carbon fiber plate. But if you want to have a 3D carving things become more complicated.

You will need to use a program like Fusion 360 that will allow you to design and edit models in its CAM mode. Using this you can set the correct cutting heights and depths then save it as an NC file for use with the Snapmaker. There are also some NC files available at Thingiverse if you want to try them. I was going to give it a try, unfortunately, I snapped the milling bit I needed before I could.

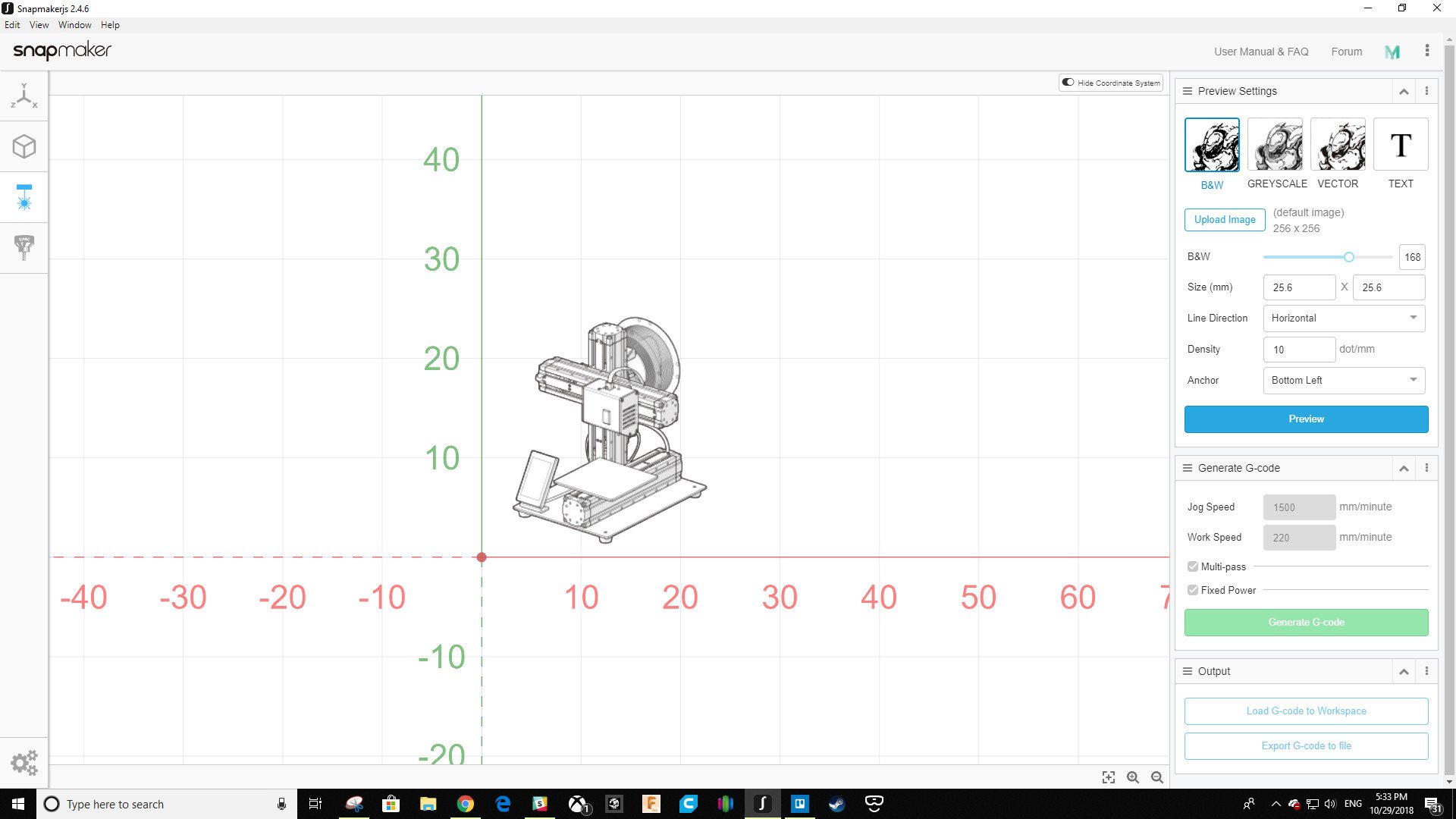

The software that Snapmaker uses is called Snapmaker.js and it is surprisingly powerful. With sections for all three modules, it allows you to load your models or files into a virtual workspace where you can prepare to bring them into the physical world.

Although Snapmaker supplies profiles for both Cura and Simplify 3D the two most popular slicers for 3D printing, I found myself using its own software as it simply worked every time I used it.

What you won't love about Snapmaker 3-in-1

The Snapmaker really has only one flaw. The laser etcher, while still being my favorite module, is weak. At only 200mW, the laser can only etch certain materials and cannot cut through any. I would have loved to see it be able to etch aluminum or glass from the get-go, but it just doesn't have the power. Snapmaker has released an enormous 1600mW laser capable of etching just about anything and even cutting through acrylic plastic and thin wood. At $129, it isn't terribly pricey, but a middle ground for the stock laser could have been reached to allow more versatility than it currently has.

So should you buy Snapmaker 3-in-1?

Aside from the small laser issue and the build plate being smaller than I would like, the Snapmaker 3-in-1 is an excellent machine for anyone looking to get creative. The modular design is beautiful and the three modules do a great job at starting you on the road to becoming a creator of all the things.

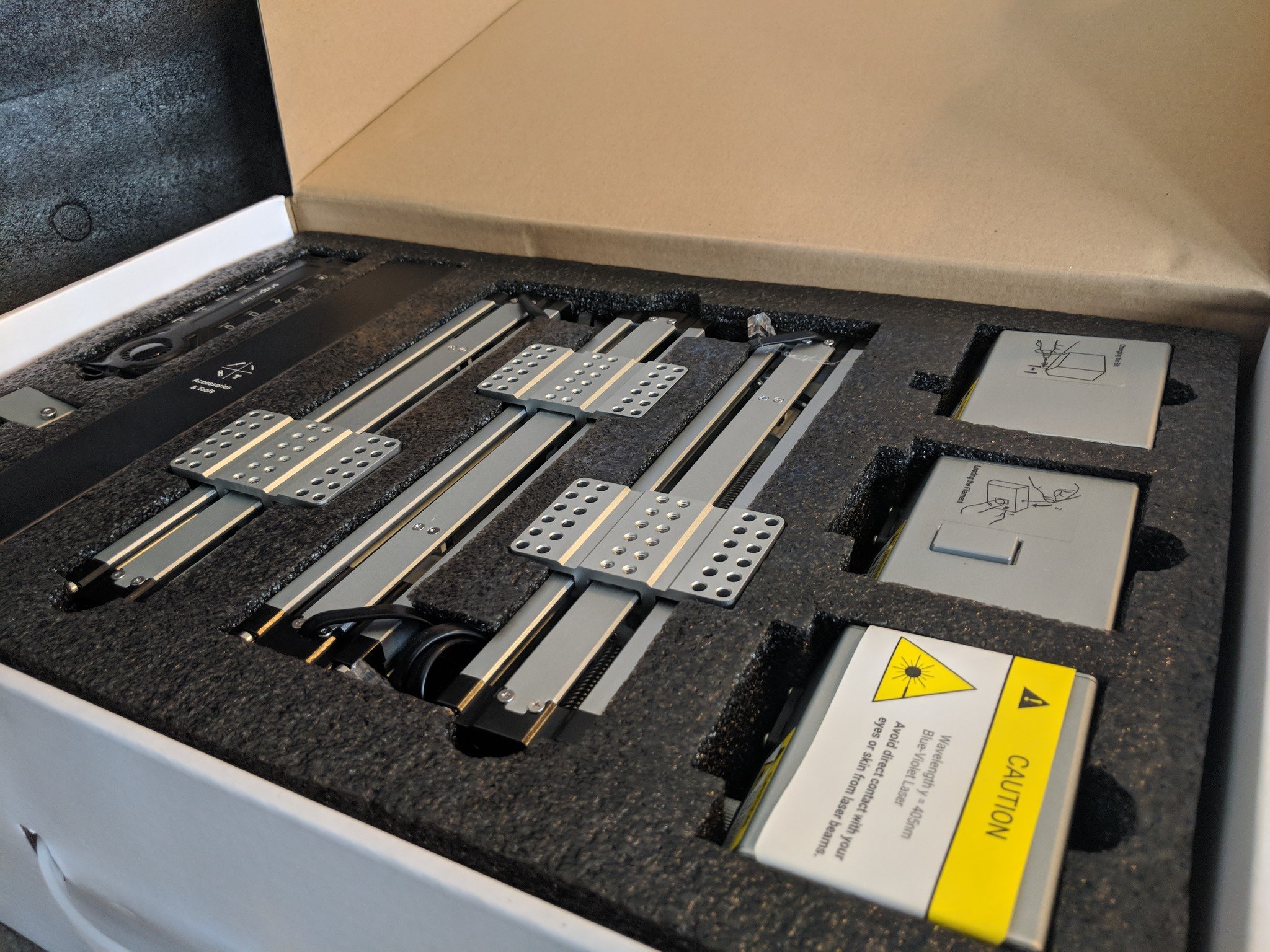

This may be a small thing to some people, but the Snapmaker is so well packaged it borders on a work of art. Each individual piece is lovingly wrapped in a solid foam and split into easy to find sections. When you have to build something from scratch, having a well laid out box at the start makes everything easier.

So, yes, you should buy one if you're in the market for a new 3D printer or a fabrication package.

James is a Former Contributor who built his first PC when he was 13 and has never looked back. He can be found on Windows Central, usually in the corner where all the 3D printers are, or huddled around the Xbox playing the latest games.