Resin or filament 3D printing: Which is best for you?

What do all those acronyms mean?

Resin or filament 3D printing: Which is best for you?

Best answer: You'll want a filament (FDM) printer for printing large models such as cosplay accessories. Resin (SLA/DLP) printers are best for miniatures with extra detail like tabletop game pieces.

What is filament (FDM) printing?

Fused deposition modeling (FDM) is the style of printing most people recognize. A string of plastic called a filament is melted through a hot end and deposited on the build plate, and the next layer is then placed on top of the previous layer.

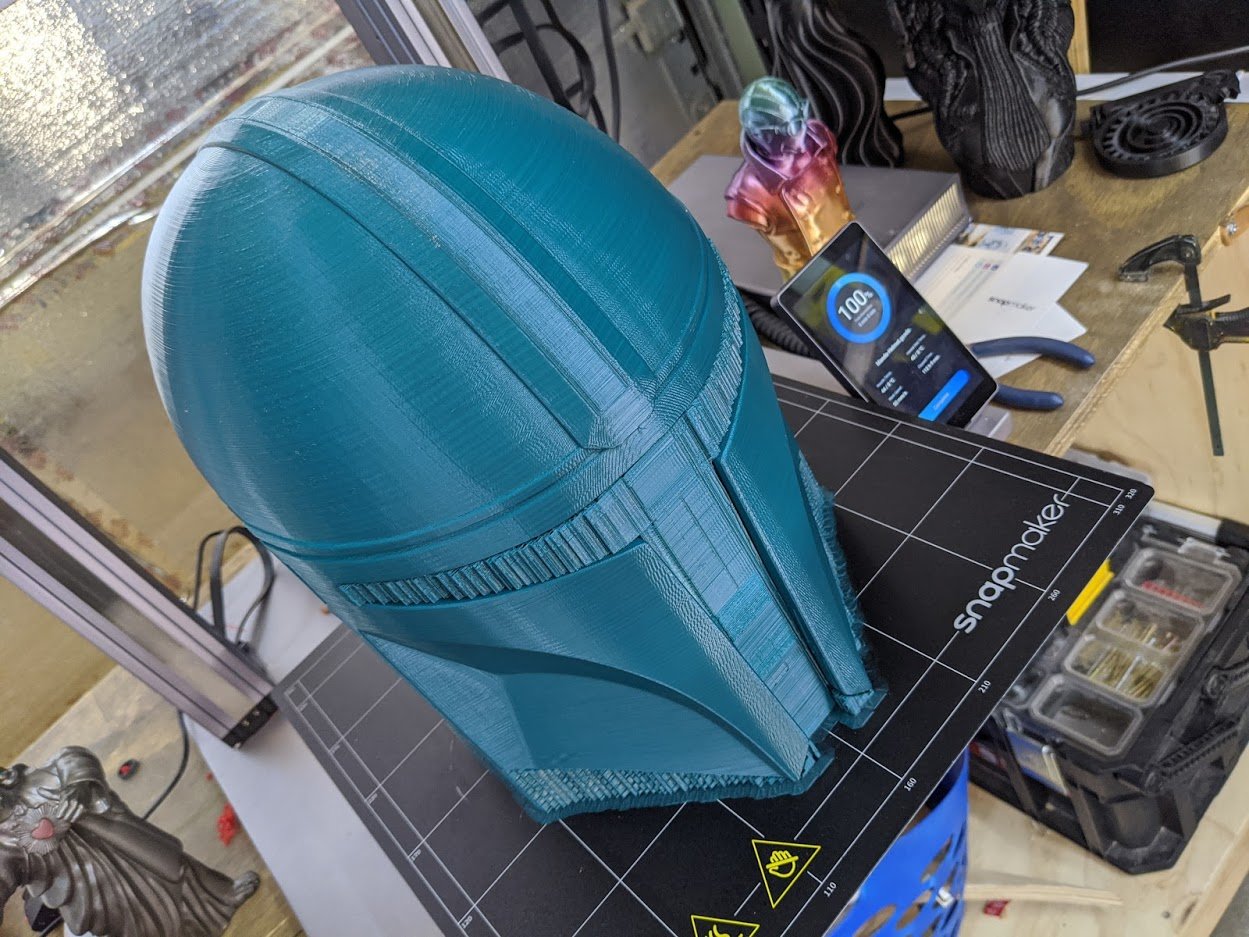

FDM printing is used far and wide in modeling and producing larger parts like cosplay armor and helmets. The nature of the printing makes it very easy to set up and very easy to learn. Most maker spaces around the country use FDM printers as they are cheap and reliable, with plenty of options for 3D printing filament on a budget.

FDM printing is also very good at making practical prints. Many printers can print exotic materials like carbon fiber and nylons that are incredibly strong. These can be used to make strong models and moving parts.

When you want to make smaller models in finer detail, FDM printing can run aground. That isn't to say that a well-tuned FDM printer can't give you incredible detail; they can. If you look at the Joker model we used by Wekster, you can see that although the model isn't as smooth as the resin version, it still looks excellent.

What is resin (SLA/DLP) printing?

Stereolithography/digital light processing (SLA/DLP) printers are 3D printers that print using light to cure liquid resin into layers. The cheaper versions use an LCD to shine a UV image into the resin, which cures it into a solid layer. The print bed then rises slightly to let the next layer cure.

Resin allows you to print a model with fine details, far more than a standard FDM printer can produce, and the result tends to need far less post-processing work to give you a finished product.

The downside is that they tend to have smaller build plates than FDM printers, so you can't make large pieces on them. Resin also tends to be a little slower than filament as it needs to cure. You will also have to wash the model afterward to get the full effect.

All the latest news, reviews, and guides for Windows and Xbox diehards.

There have been great strides to solve both these problems, though. You could buy the excellent Anycubic Wash and Cure V2 station and considerably speed up the curing process. There are also enormous options like the Peopoly Phenom resin 3D printer that will print your parts on a much larger scale, providing the best of both worlds.

Which should you buy?

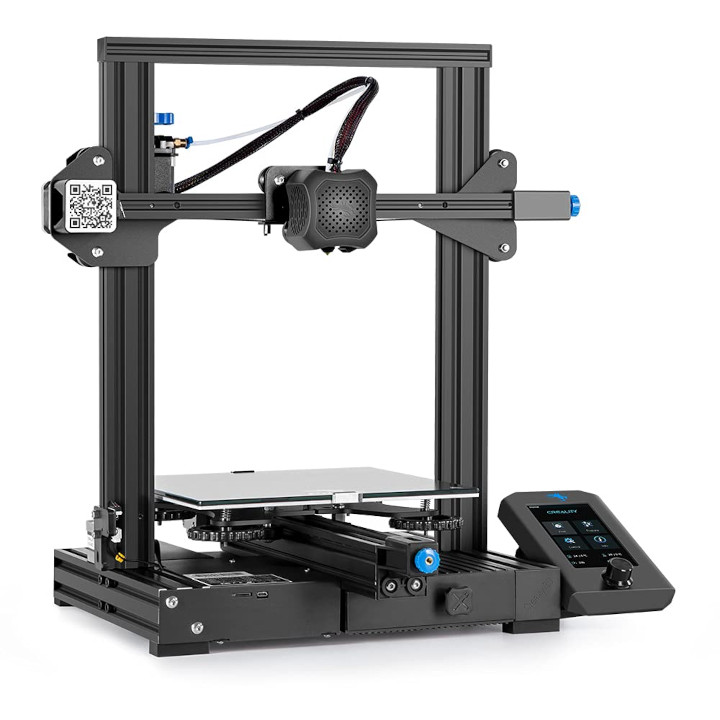

To build large-scale models, cosplay items like armor and helmets, or produce prototypes rapidly, an FDM 3D printer is likely the right choice. It gives you the greatest range of options, often at a reasonable price. The Creality Ender 3 V2 is an affordable way to start filament printing and features a resume function, so you won't lose progress on a print if there's a power cut.

For a first-time FDM 3D printer, you won't break the bank with the Creality Ender 3 V2. Its features and print quality make it one of the best 3D printers you can buy on a budget.

If you are hoping to print miniatures for board games, highly detailed models, or production-quality parts, then a resin (SLA/DLP) printer is best. The level of resolution that a resin printer can bring is extraordinary if you're willing to take a few extra steps to cure and clean your models. The Elegoo Mars has the right entry-level price for newcomers. The Mars is a revelation for anyone who has never used a resin printer before as it is so cheap and yet produces amazing prints every time.

The Elegoo Mars is impressive. For far less than you might think, you can have a resin printer that makes amazingly detailed models reliably.

Ben is a Senior Editor at Windows Central, covering everything related to technology hardware and software. He regularly goes hands-on with the latest Windows laptops, components inside custom gaming desktops, and any accessory compatible with PC and Xbox. His lifelong obsession with dismantling gadgets to see how they work led him to pursue a career in tech-centric journalism after a decade of experience in electronics retail and tech support.

- James BricknellFormer Contributor, 3D Printing