3D printing has come a long way since I first started playing around with the medium. We now have a huge variety of 3D printers at every price point imaginable. The $300 printer market is a much sought after area to break into — and a common subject in the 3D printing groups on Facebook — with a lot of companies vying for their place at the table.

Does the Monoprice MP10 Mini manage to break into this market and make a real change? Sort of ... but it's a mixed bag.

$300Bottom line: The MP10 Mini offers a lot of valuable features, with a stable foundation and some wonderfully advanced safety features. There a few underlying issues, but if you are patient and persistent, the MP10 Mini could be a really great machine.

Pros

- Great price

- Some nice advanced features

- Solid construction

Cons

- Will need a lot of tuning

- No really, I mean a lot of tuning

What you'll love about the MP10 Mini

The MP10 Mini is something of an anomaly. Originally based on the MP10 — Monoprice's large scale printer, which in turn is based on the CR10 by Creality — The MP10 Mini is a cut-down machine but featuring all the same design features as its big sister. So it's the small version of a large version, instead of the other way round as is normally the case.

The MP10 series uses a slightly different mechanism than most of Monoprice's printers. It uses the same extruded aluminum struts to create the frame, but instead of using greased rods to move the build plate and z-gantry, it uses low friction rollers. This is something Creality has been doing for a while now in its Ender and CR10 models, and it seems to work very well to reduce noise on the prints on these Monoprice variants, too.

The MP10 Mini has the potential to be amazing.

When you first take the printer out of the box, it takes just a few screws to bring it all together, making an extremely sturdy printer. There are also a lot of nice features on the Mini that you would expect to see in a much higher priced machine, features like automatic bed leveling, filament run-out, and, my personal favorite, a quick-release print head.

The print head itself is attached to the gantry with three very strong magnets. This turns out to be extremely helpful in a number of ways. It makes changing the nozzle much easier, for example, but it also means you aren't likely to break anything if you get the settings wrong on your print and you crash into the build plate or into the model. The print head just comes loose instead of bending or breaking anything.

I would also say that you want to keep an eye out on the filament run-out sensor. This one seems to be especially sensitive and doesn't really like bright colors like white, silver, or clear. It doesn't work at all when you try to use clear. As I used the machine more and more, I chose to disconnect the filament sensor completely as all the false positives were making printing anything tough.

All the latest news, reviews, and guides for Windows and Xbox diehards.

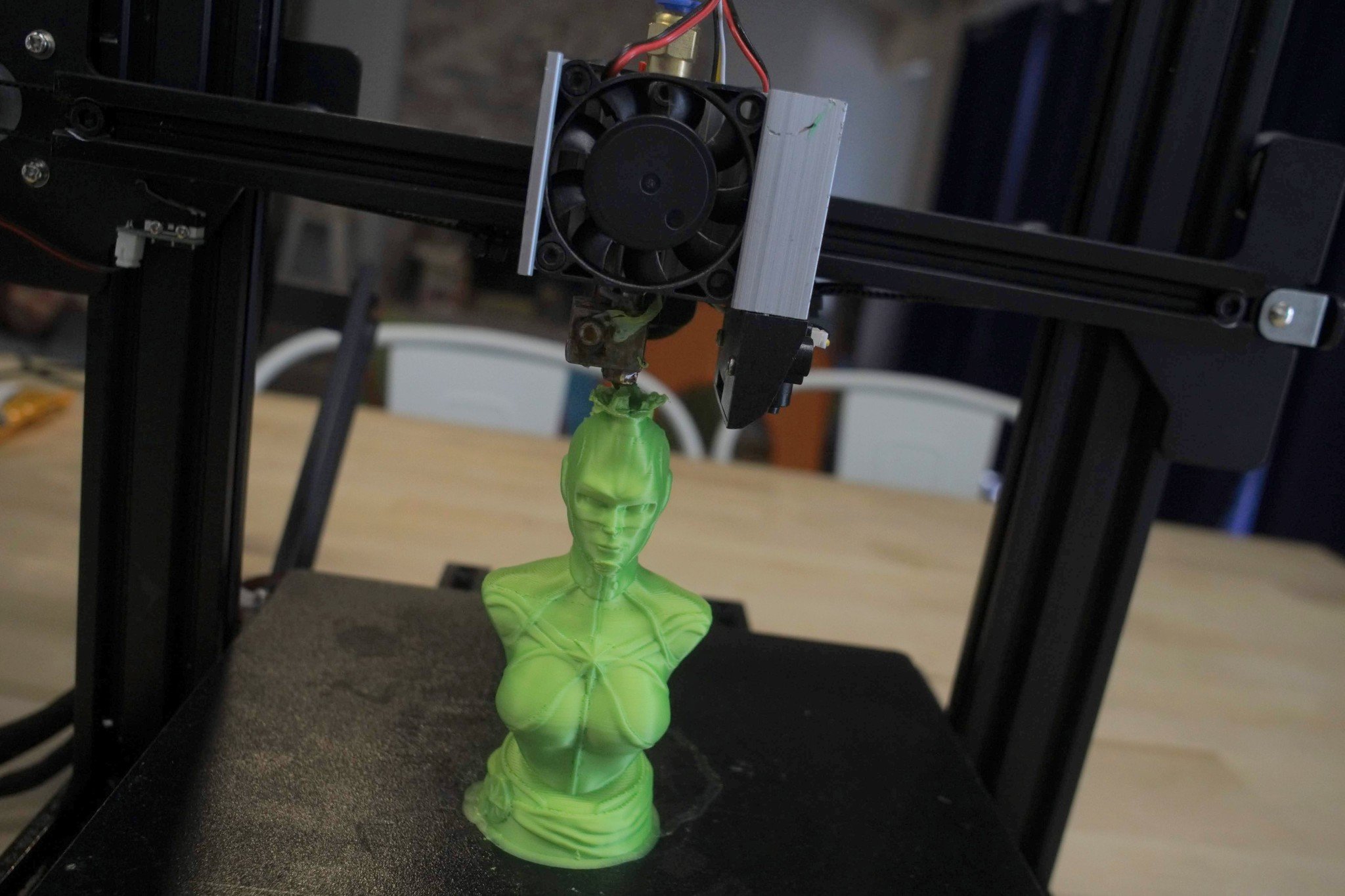

Despite these issues though, when I finally got the MP10 Mini dialed in and printing well, the results were as good as any printer in its price point and even a few $100 to 200 options. There are some really nice layer lines on the Cyclops model I printed by Wekster, and although I didn't get the number of top layers quite right on Captain Marvel (below), you can see the potential in this machine.

What you'll dislike about the MP10 Mini

My biggest issue with the MP10 mini is the quality when you first unbox it. 3D printing isn't new, and affordable printers are becoming more and more common, so new printers should be capable of printing excellent prints out of the box. This simply wasn't the case with the MP10 that I used.

The first thing I print whenever I get a printer to review is the Gcode on the SD card that comes with it. For those who don't know, Gcode is the file that tells your printer how to print the model — STL, OBJ, or 3MF are the actual models — and most companies include one that has been tuned and generated to give the printer its very best chance to impress you. Unfortunately, the MP10 mini couldn't even successfully print the fortune cat that comes with the printer, despite several tries, and although the quality of the print was great, it doesn't matter if it can't get through it.

These kinds of issues make the MP 10 Mini slightly tougher to recommend. There are plenty of people out there who love to take the time to really fine-tune a printer and make it their own, and they do an amazing job. For $300, the MP10 is a great place to start on your 3D printing journey if you have the time, patience, and enough filament to really dial it in.

The potential is there, but if you are hoping to print excellent prints out of the box, there are other printers you can consider. The Monoprice Mini Delta works almost perfectly out of the box, and although the build plate is small, the print quality is amazing straight out of the box.

So should you buy the MP10 Mini?

I'm of two minds about the MP10 Mini from Monoprice. I think, given enough time, I could make this printer sit up and dance the merry tune of perfect layers, but do I want to? In this day and age of inexpensive printers, should we have to work hard to create passable prints? Or should we be able to plug it in, press the button and know that a decent print is going to happen?

If you are looking for a small, yet solid 3D printer for $300, you could do a lot worse than the MP10 Mini. If you stretched your budget just a little further to $400, you could get yourself the full-size MP10, though, and that has all the same features with a 300 mm x 300 mm build plate, 50 percent bigger than the MP10 mini.

Still, the MP10 Mini has the potential to be amazing. You just need the patience to get it there

James is a Former Contributor who built his first PC when he was 13 and has never looked back. He can be found on Windows Central, usually in the corner where all the 3D printers are, or huddled around the Xbox playing the latest games.