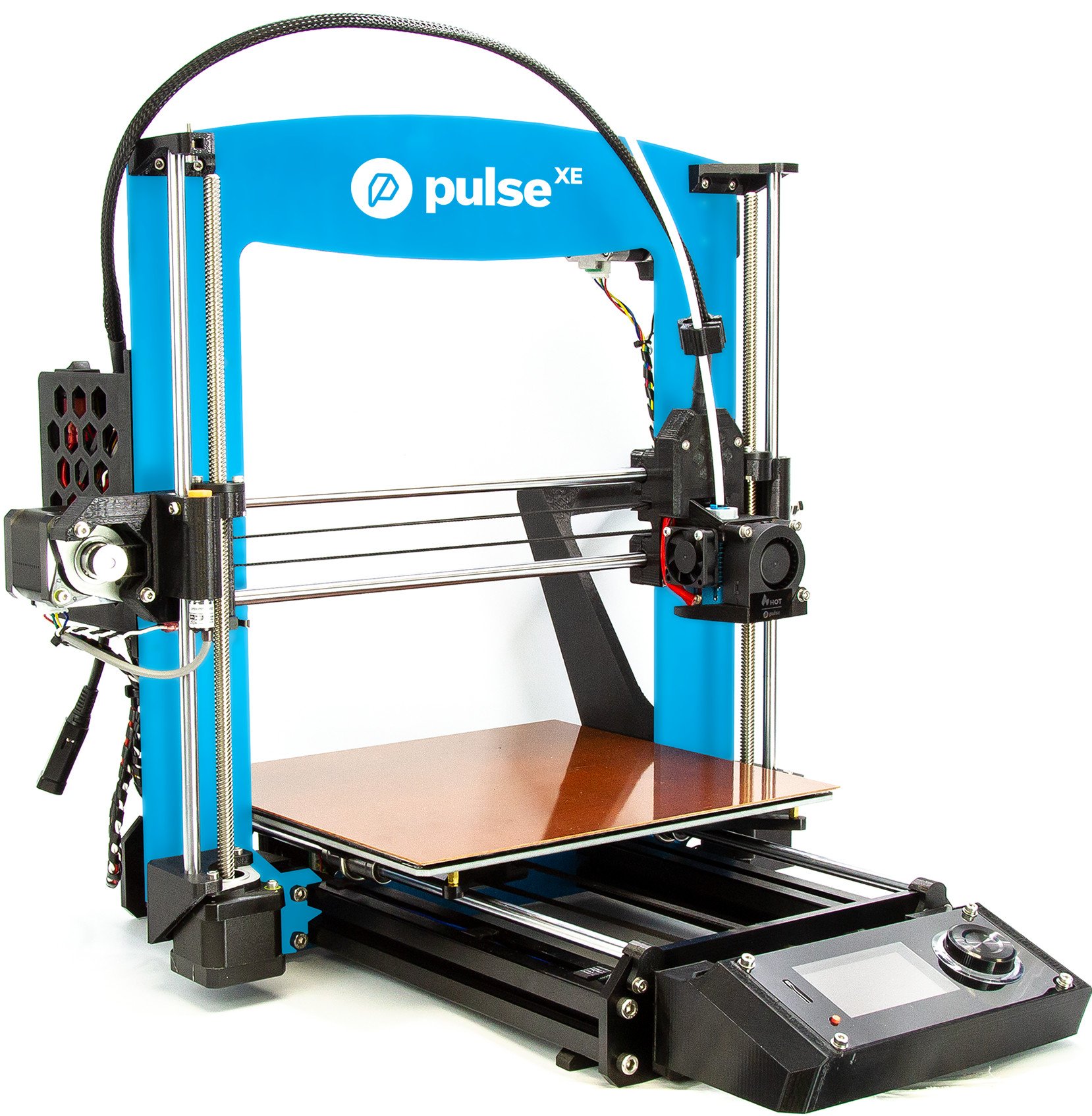

There are a lot of 3D printers out there that are based on the Prusa i3 printer. Most of them are not very good, using terrible materials and parts to make the cheapest 3D printer they can. The Pulse XE from Matterhackers is the opposite of that in almost every way.

The Pulse XE is a well-tuned machine, specifically designed with the very best components available, rather than the cheapest. It is precision engineering, mixed with open-source technologies, that has created an absolute workhorse of a machine. The Pulse XE is not just for making fun models that you can show on twitter — though it can do that well too; it's for making seriously tough manufacturing parts.

$1,000Bottom line: The Pulse XE is not for everyone. It's for those makers who want to work with more exotic materials, and it works very, very well. But you pay for it.

For

- High-quality parts

- Allows for a huge variety of filaments

- Bondtech extruder

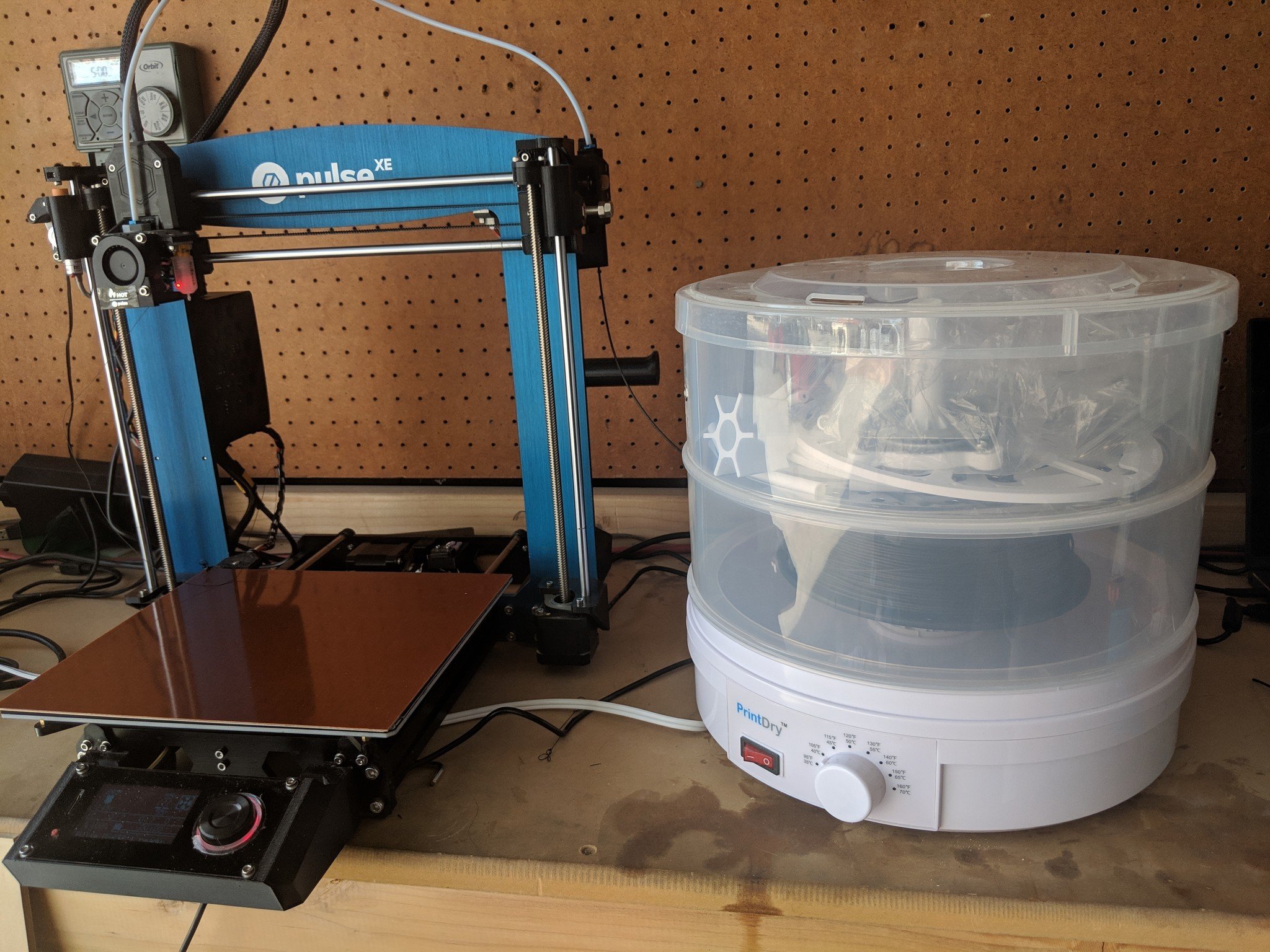

- Comes with PrintDry and Ryno filament

Against

- LCD interface can be confusing

- Needs a controlled environment

What you'll love about Matterhackers Pulse XE bundle

When I first started using the Pulse XE I was ready to complain. After all, I have used four or five different 3D printers built on the Prusa blueprint, and how different could the Pulse XE be to warrant it's $1,500 price tag?

This thing is built like a tank. The frame is made of solid aluminum and it is thick, much thicker than other brands. While it may add some weight, it also adds a huge amount of rigidity to the entire machine. This is a printer designed to last and to print for hours, or days, without error. On my workbench, the Pulse XE doesn't move around at all when it prints, and stability is the cornerstone of a good print.

Pulse XE doesn't move around at all when it prints, and stability is the cornerstone of a good print.

One of the first things you do when you buy a 3D printer is research what upgrades you need to buy to make it work in the way you want it. New extruders, build surfaces, and nozzles are always high on the want list. The Pulse XE makes upgrading obsolete. Everything you need has already been upgraded.

The printer already comes with a Bondtech extruder and E3D hotend that can heat up to 300 degrees Celsius (572 degrees Fahrenheit), more than hot enough to deal with just about any filament out there. The Bondetch extruder itself is a work of art. It uses a different mechanism than the standard extruders and feeds filament by applying pressure to both sides. This makes the Bowden setup far more reliable and allows you to print softer filaments like TPU with a much higher rate of success.

When you are printing with exotic materials like NylonX or high-temperature filaments like RYNO the importance of good build adhesion cannot be overstated. The Pulse XE comes with a LayerLock Garolite removable print surface, perfectly designed for NylonX. It holds prints firmly while printing and lets them pop off when they are cool. It even works on other filament types, but the Pulse XE has a Buildtack base as well, in case you prefer that.

The Pulse XE comes with a lot of small details that make sure your print has every chance to be successful. With automatic bed leveling, filament run-out sensor, and a power-loss recovery system, the printer is actively trying to keep your printer printing as long as possible.

Matterhackers even bundles the Pulse XE with its own slicing and print monitoring software MatterControl. As a person who owns multiple brands, I normally prefer a more generic slicer, one that works with all my printers but as part of the review, I spent a lot of time with MatterControl. And it's really good. By connecting your 3D printer to your laptop, you get far more control than you would from just printing from the SD card. Of course, it also comes with more chances for the print to fail. If your laptop crashes, or if Windows decides you really need that update, you could lose your entire print. MatterControl features an excellent power-loss recovery mode though which makes it worth using. As long as you don't move the print after a power cut or PC crash, MatterControl will be ready to continue right where it left off.

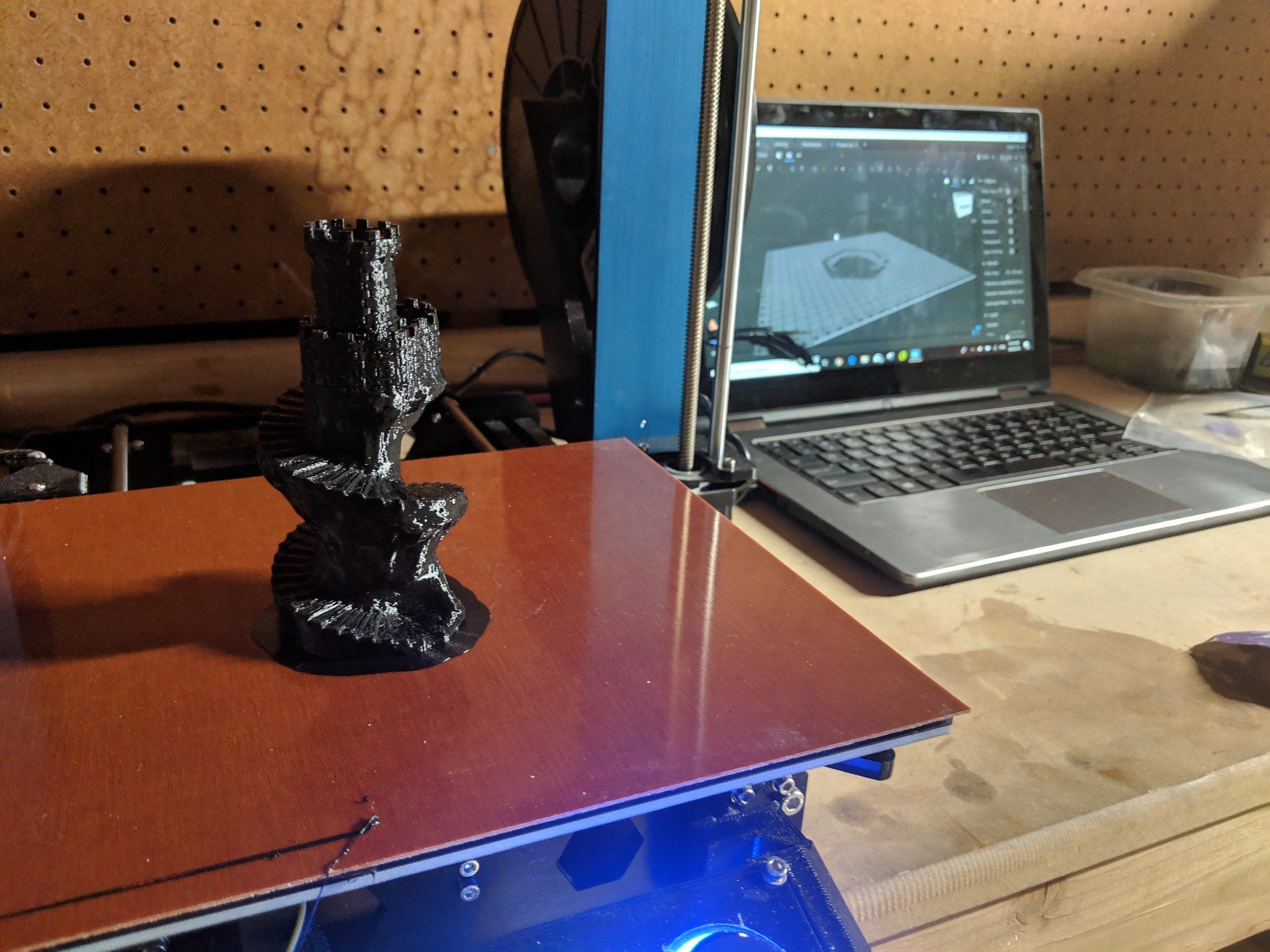

While the Pulse XE is designed to print models that can be used in tough conditions, that doesn't mean it can't make great hobbyist models, too. I used RYNO, NylonX and Matterhackers glow in the dark PLA to create some of Kijai Designs best models.

As you can see, the Pulse XE made quick work of the models and kept almost all the details you would get from any normal printer. The NylonX lost some of the details on the spiral tower, but the Olsson Ruby nozzle did a great job extruding the filament evenly, no mean feat when you are using filaments that can ruin nozzles.

These filaments are really rough on nozzles, especially brass ones. The NylonX has carbon fiber in it to make it strong and it acts like sandpaper on wood. The ruby in the Olsson nozzle is pretty much immune to wear and will deal with all your rough filaments with ease.

We can't really talk about the Pulse XE without mentioning the ease at which it deals with extremely tough filaments to print. NylonX, one of Matterhackers own brands is an extremely tough, carbon-fiber-infused, filament designed to help you create parts that are are strong and functional but can be incredibly difficult to print on a normal printer.

I have been meaning to put up shelves for my filament for a while now and this seemed like the best time. With the brackets designed by Joel Telling I set about using the NylonX to create them. I loaded everything into MatterControl, told the software I wanted to use NylonX and clicked print. The result came out almost perfectly the first time. Some of the holes weren't perfectly round, but with a few tweaks to the speed, I had it dialed in. As you can see from the above picture, the brackets are strong enough to hold a lot of filament without any trouble at all.

What you might not like about Matterhackers Pulse XE

There really isn't much to dislike about the Pulse XE. Would I like the onboard controls to be a little clearer? Sure. Some of the controls don't feel intuitive when you scroll through all the choices, the axis movement, for example. You have two main choices on the LCD control, Prepare and Control, but instead of the axis movement being in Control, they are in Prepare. This doesn't make sense to me.

But really this is just nitpicking. Matterhackers has clearly gone all-in on MatterControl rather than the onboard controls and the software more than makes up for the confusing LCD. MatterControl is intuitive with plenty of controls, in all the right places to help you print successfully. Still, I would like to see the bed leveling wizard available on the machine, not just on the software.

The final thing is more of a warning than a reason not to buy. You will need to look carefully at the location you are putting the Pulse XE. Because you will likely be using exotic filaments, you want to make sure the printer and the PrintDry machine that comes in the bundle have enough space and a constant environment to work in. A lot of these filaments are extremely susceptible to water in the air so using a swamp cooler in your workspace is likely to cause issues.

Now, the PrintDry system that comes with the Pulse XE does an admirable job at controlling the filaments moisture content you will need to make sure your environment is the very best it can be. Of course, if you are looking to buy an exotic filament 3D Printer you are likely to already have a great workspace, but it is worth highlighting.

Should you buy the Matterhackers Pulse XE bundle?

Matterhackers has chosen a very specific path with its Pulse series of 3D printers. Instead of creating generally good printers, the company created generally good machines with a hyperfocus on a specific 3D printing problem. The Pulse XE is a good printer for general use, but what makes it truly great is the ease at which you can print filaments beyond the norm. NylonX, RYNO, TPU, glow-in-the-dark, and metal infused filaments are all really fun to use and can be extremely difficult to get right. The Pulse XE makes these far easier to print with success.

I would recommend the Pulse XE to anyone thinking of moving beyond the limitations set by PLA and ABS filaments. The build quality and use of the very best upgrades sets this printer apart from just about any other i3 clone. If you want to make something a little different from the norm, this is the printer for you.

James built his first PC when he was 13 and has never looked back. He can be found on Windows Central, usually in the corner where all the 3D printers are, or huddled around the Xbox playing the latest games.