Got a 3D printer? Here's how you can join the fight against coronavirus.

There is always something ordinary people can do to help those who are risking everything to keep us safe.

Unless you have been taking social distancing and working from home to an extreme level, you will likely have seen the news surrounding 3D printing and the coronavirus (COVID-19).

The good news is that there are ways you can contribute to the efforts to combat coronavirus, from home, using your 3D printer. Several different people have tried to help local hospitals by 3D printing parts, with mixed success. If you have a 3D printer, there are ways you can help without risking yourself or others.

- What you shouldn't make

- What you can (and should) make

- What you'll need to make face shields

- Additional resources

What you shouldn't make

I know people are desperate to help, but there is a lot of misinformation, making the whole process harder. You will likely have seen articles about the Italian makers who were supplying parts for ventilators and that they were sued for using a design based on a companies IP. This is not a situation that anyone wants to find themselves in. So what should you stay clear of when making stuff to help?

Ventilator parts

Hospitals are soon going to be in desperate need of ventilator parts, and despite our desire to help, these parts can't be made from home. Ventilator parts will need to be of the highest standard to work correctly and be free of all contaminants. 3D printing them on an FDM printer will leave the part porous and subject to germs build-up, while the resin we use at home is toxic, even after it's been cured, so it isn't viable either.

For now, stay away from these and let the professionals work on them. Elon Musk has already said Tesla will be working to make ventilators that are safe and secure, so we have to hope that it's enough.

Face masks

This one feels like something we at home could do. There are a lot of designs out there, and people are trying hard to make the right type, but there are several issues with making these for doctors. Like the ventilators, these face masks would be porous, allowing bacteria and the virus to get trapped between the layers. They are also rigid, so making a tight seal is almost impossible, and a seal is an essential part of a mask. They are also extremely hard to make comfy for long periods.

What you may be able to do is print masks for your friends in construction and ask them to donate their N95 masks to the local hospitals and doctor's offices. Really though, the best solution for helping combat the virus has come from a huge name in 3D printing.

Get the Windows Central Newsletter

All the latest news, reviews, and guides for Windows and Xbox diehards.

What you can make

Face Shields

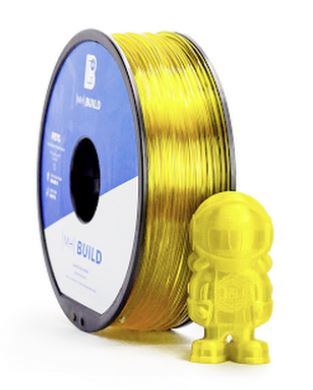

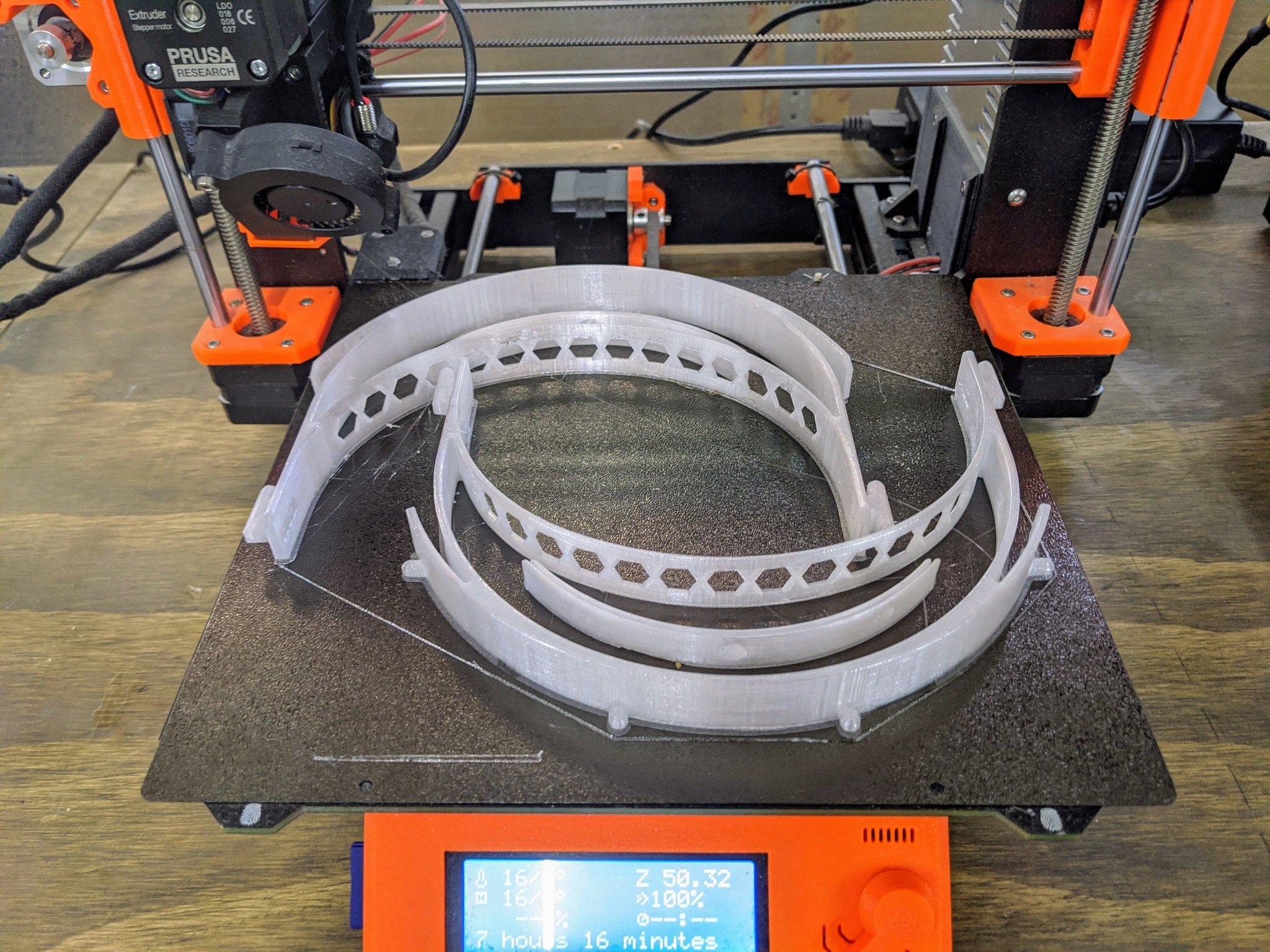

If you are into 3D printing, you will likely already know the name Josef Prusa, creator of the Prusa I3 range of printers. Josef and his team have been working with medical professionals to design a face shield that you can print at home easily and safely for the doctors in your local area, and what they have come up with is likely your best choice for helping.

Face shields are an incredibly helpful piece of PPE for healthcare professionals. Because the coronavirus transmits through water droplets, anything that can protect you from liquid contact — especially contact to the face — is going to decrease your odds of contracting the virus a lot. These face shields are easy to use and can be produced rapidly.

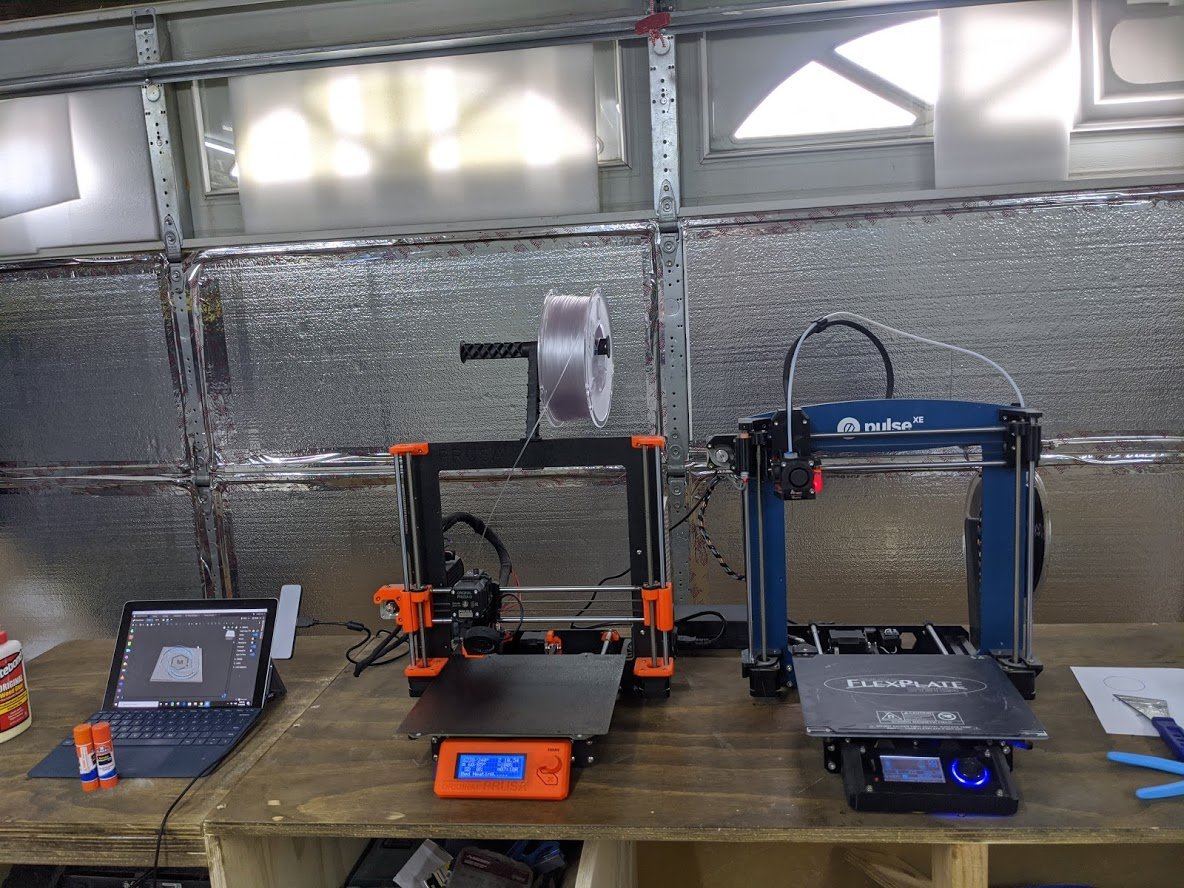

It's not just the team at Prusa, either; there are now groups of people all over the world printing this design and shipping them to hospitals. Even I, with just my two printers, have been making them. I can make roughly 12 a day if I print nonstop — that's around 80 a week — so imagine what we could do together.

Ear Savers

With more and more of the US being told to wear masks whenever you go outside, these ear savers can come in very handy. Everyone, from medical professionals to grocery store workers are having to wear masks for 12 + hours a day and these little things can be very helpful. I am currently printing 11 per hour and taking them to my local grocery store. From there they are given out to customers to help keep people comfortable.

They are incredibly easy to print and there are hundreds of variations. I like this model from sniffle as it is lightweight, flexible and very quick to print. You won't need any fancy materials for this either, just straight PLA works perfectly as it is flexible at low layer heights.

What you'll need to make face shields

To make these yourself, you will need to check out the article from Prusa Research first. This will give you tips on how to print the face shield and how to make it as safe as possible. One of the most important parts of the process is to assume you have the virus. When making these shields, you should be wearing a face mask and disposable gloves where at all possible. As soon as the prints are done, you will need to put them into a sealable plastic bag to keep them from any contamination.

There are essentially only three parts to the face shield designed by Prusa, so if you want to build them as complete items, you will need to get some parts in stock.

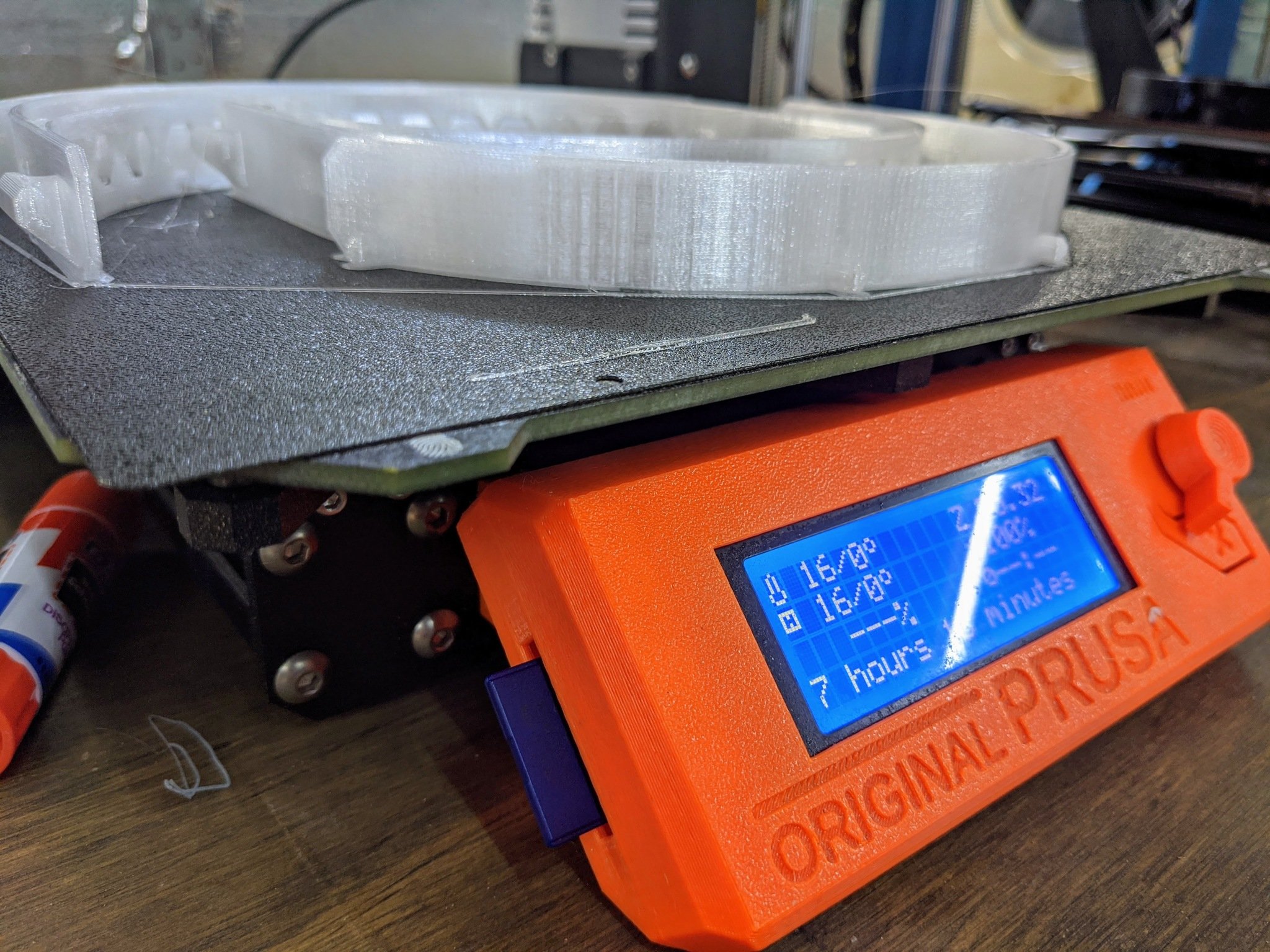

Petg is easy to print and has excellent durability properties. It's easy to sterilize too, so it's the best choice for masking making.

While you can make 3D printed parts out of almost any plastic, Petg is the best choice. It's a little tougher to print than PLA — the temperatures needed are a little higher, and you'll need to print it slowly — but it can withstand higher temperatures, making it easier to sterilize at a hospital.

To make the head strap comfortable for long periods, this kind of band is the best.

The team is using buttonhole elastic at Prusa, and the face shield is designed with that in mind. You can pick up quite a lot for cheap, enough to let you make a nice amount of guards in one go.

Acrylic sheet

This is perhaps the hardest part to find and make. First off, 0.5mm clear plastic isn't as easy to find as you might think, and it'll need to be at least 240mm x 240mm to be usable. Once you've found a source, you'll then need to cut all the holes with a laser cutter, and unless you already have one buying them can be expensive.

Because of this, companies and maker spaces all over the world have stepped up to help. Joining one of these teams as a volunteer is likely the best way for you to help on a larger scale.

Resources for you

Right now, the best way for you to help is to print the parts and ship them to one of the many businesses and maker spaces that are helping out in this crisis. I have a few here for you to contact and will add more as they become available.

- Masks for Docs (West coast USA)

Masks for Docs is not just producing face shields but gathering up any n95 face masks that people donate and bringing them to hospitals on the west coast of the US. If you can't get access to the plastic sheets needed for the face masks and you want to help, then contact the team here, and they will guide you through the process. This is the team I'm currently working with, so my 80 3D printed parts will go to the team at Repbox who will pack them up with the elastic and screens to ship them away. If you are a 3D printing Hobbyist, this is likely the easiest way to help.

- Baltimore makers (East coast USA)

A group of makers and maker spaces over in the Baltimore area are working hard to print as many face shields as possible. Like Mask for Docs, they have a system in place on how you can help, and you can fill in a simple form to get yourself on the list. Having teams on both coasts are going to be essential if we are going to help the most amount of people.

- Matterhackers (USA)

Matterhackers is in a unique situation to pull in a lot of information from all over the country. The company has created a hub for all the information we have about COVID-19 and has multiple sign-up points to help you find the most appropriate ways for you to help. Matterhackers recently announced that over 9000 face shields had been donated by their partners so far, and that number keeps climbing. You can also use the code COVID15 to get 15% off Matterhackers Pro Series Petg to help you make as many shields as possible.

We can all help

I'm a big believer in humanity. When push comes to shove, we try to help each other out, and the maker community is a unique position the help more than most. If you have a sewing machine and material like our own Jen Karner, you can make face masks, if you are a construction worker, you can donate N95 masks to the local hospitals, and if you are a 3D printing hobbyist, you can make faceshields.

The world is scary right now, so let's try and help where we can.

James built his first PC when he was 13 and has never looked back. He can be found on Windows Central, usually in the corner where all the 3D printers are, or huddled around the Xbox playing the latest games.