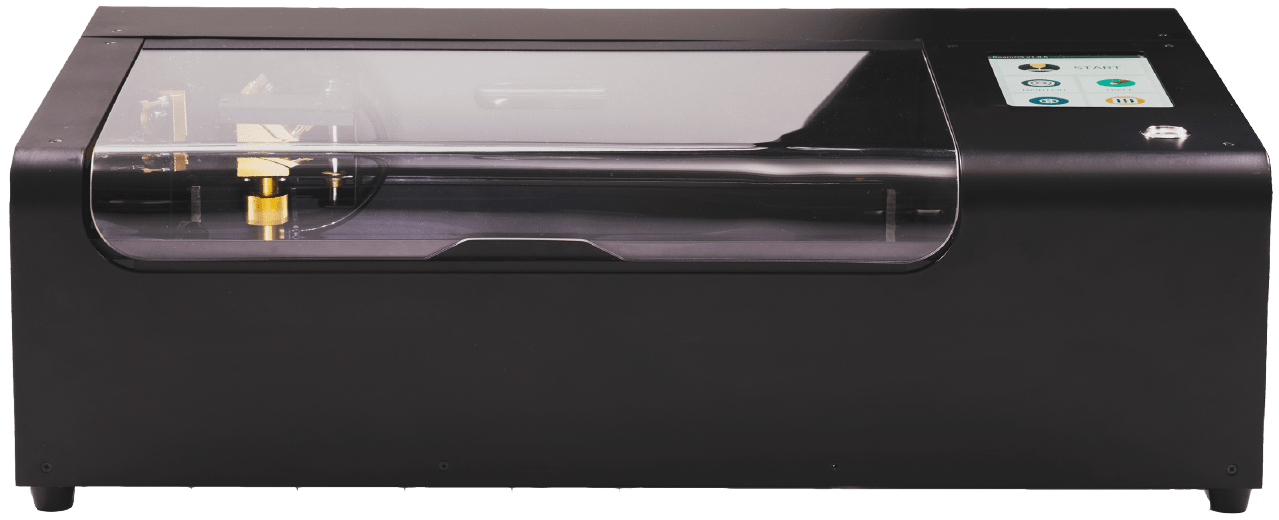

When you get the creator bug, you want as many ways to create as you can. Whether you are a hobbyist 3D printing maker or a teacher creating a maker-space, the Beamo laser cutter from FLUX is pretty much the perfect tool for you. It lets you create on just about any surface you can think of for a fraction of the cost of other carbon dioxide lasers.

Bottom line: The Beamo from FLUX is the perfect price point to allow schools, hobbyists, and maker-spaces to diversify their making options. While it doesn't have as many options as other laser cutters, it is half the cost, and what it does, it does exceptionally well.

Pros

- Compact size

- Wireless connection

- Can cut a huge variety of materials

- Built-in extraction

- Removable base for larger etchings

Cons

- Software is currently lacking options

What you'll love about the FLUX Beamo

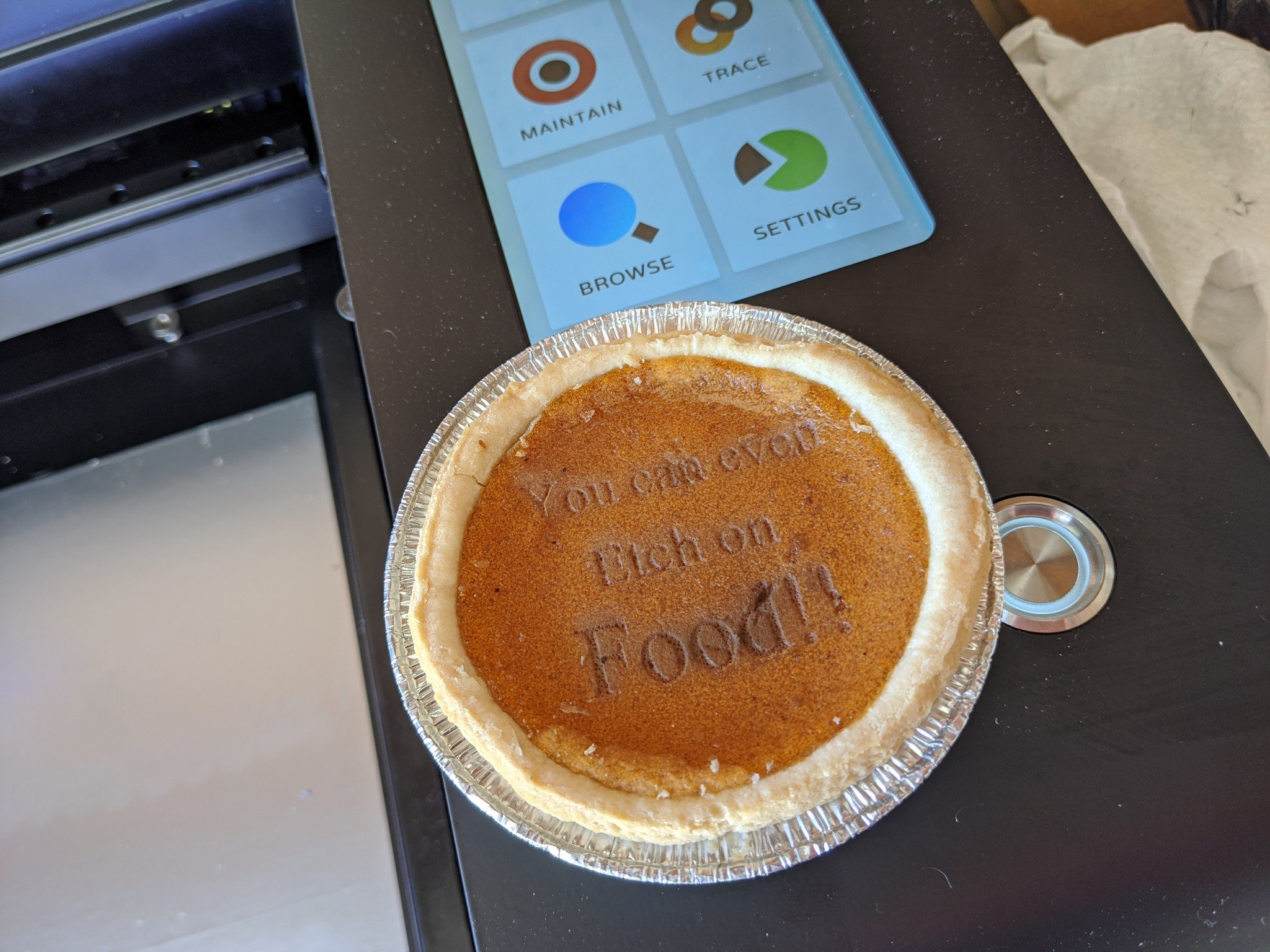

If variety is the spice of life, then the beamo is peppered with life. I have made a serious effort to use as many different materials as possible with Beamo, even some materials that FLUX doesn't mention in its list. I have etched onto iPads, phones, hard phone cases, acrylic, leather, fabricated wood, real wood, and even glass. The Beamo has etched into all of them with ease and precision. I also etched the top of a pumpkin pie, and it worked amazingly well.

Another thing to note; almost all of the things I have etched and cut have been with the laser at less than 50%, some of them have been as low as 10%. There is a lot of room for the Beamo to grow and for makers to experiment with other materials and power levels.

Source: Windows Central

The laser is equipped with water cooling, a direct air nozzle at the laser, and a powerful extraction system to control the burning around your cut. All of these things work in concert to reduce the chance of fires to a minimum, which helps focus the burning where it needs to be and not spread around your maker space.

None of the things I have done have felt beyond the Beamo's capabilities; it always feels like it has more to give.

Speaking of focus, making sure the laser is at the right height is incredibly simple; one nut to unscrew and a little piece of plastic to set the height, and you're done. To keep the entry cost low, FLUX hasn't supplied an autofocus module for the Beamo as standard, but it will be available as an add-on, along with a rotary tool for etching on to round objects. I'm especially looking forward to the rotary tool so I can add Star Trek things on my drink glasses.

I found that there is a fair amount of leeway on the focus before it becomes blurry in the actual cut. I put two different phone cases in there that had different heights. I focused the laser on the tallest case, and the lower case still cut beautifully. In fact, nothing I have tried to cut has failed, even soft, TPU phone cases etched, albeit with a little discoloration

All the latest news, reviews, and guides for Windows and Xbox diehards.

The unit itself is surprisingly small, taking up little more space than a large DeskJet printer so it can easily fit into your garage, school workshop, or other maker-space. Just make sure to use the extraction hose that is supplied to vent to the outside. I forgot, and my entire workshop filled with smoke in minutes.

One of my favorite little features is the ability to remove the cutting bed and even the bottom of the Beamo if you need to so you can print much larger pieces than the dimensions would typically allow. It also has an interesting tracing ability, called Smart Trace, which allows you to put a picture in the Beamo then convert that to an image that you can cut. This Smart Trace is coming to the machines interface as well, so you won't have to use your PC to do it.

I managed to fit a 15" Macbook Pro into the machine with no issue, and my next project is to burn a design onto my desk with the bottom removed. None of the things I have done have felt beyond the Beamo's capabilities; it always feels like it has more to give. I've used other carbon dioxide laser cutters that cost twice as much as this machine, but Beamo doesn't feel overmatched at all.

I've spoken a lot about the etching side but Beamo can also cut extremely well. There are a lot of different materials that it can cut through — it uses the laser at a higher percentage of power, at a lower speed — but a good rule of thumb is: if it's not metal or glass, it can do it. Mainly you will be looking at woods, acrylic plastic, and leather up to 5mm thick.

I made some Isolinear chips from Star Trek by etching the design then cutting the shape out of a larger piece of acrylic. As a #ProTip, I would recommend leaving the paper coating on the acrylic as you cut. Not only does it protect the plastic from discoloration but it's a built-in mask for painting. Some people even suggest masking your wood with painters tape for the same reason.

What you might dislike about the FLUX Beamo

There isn't a huge amount I disliked about the Beamo. The hardware itself is terrific for the price, with a decent-sized LCD touch panel to control it. Not that you will use it all that much as the Beamo has both ethernet and wireless — with an included dongle — so you can do almost everything you need to on the Beam Studio software.

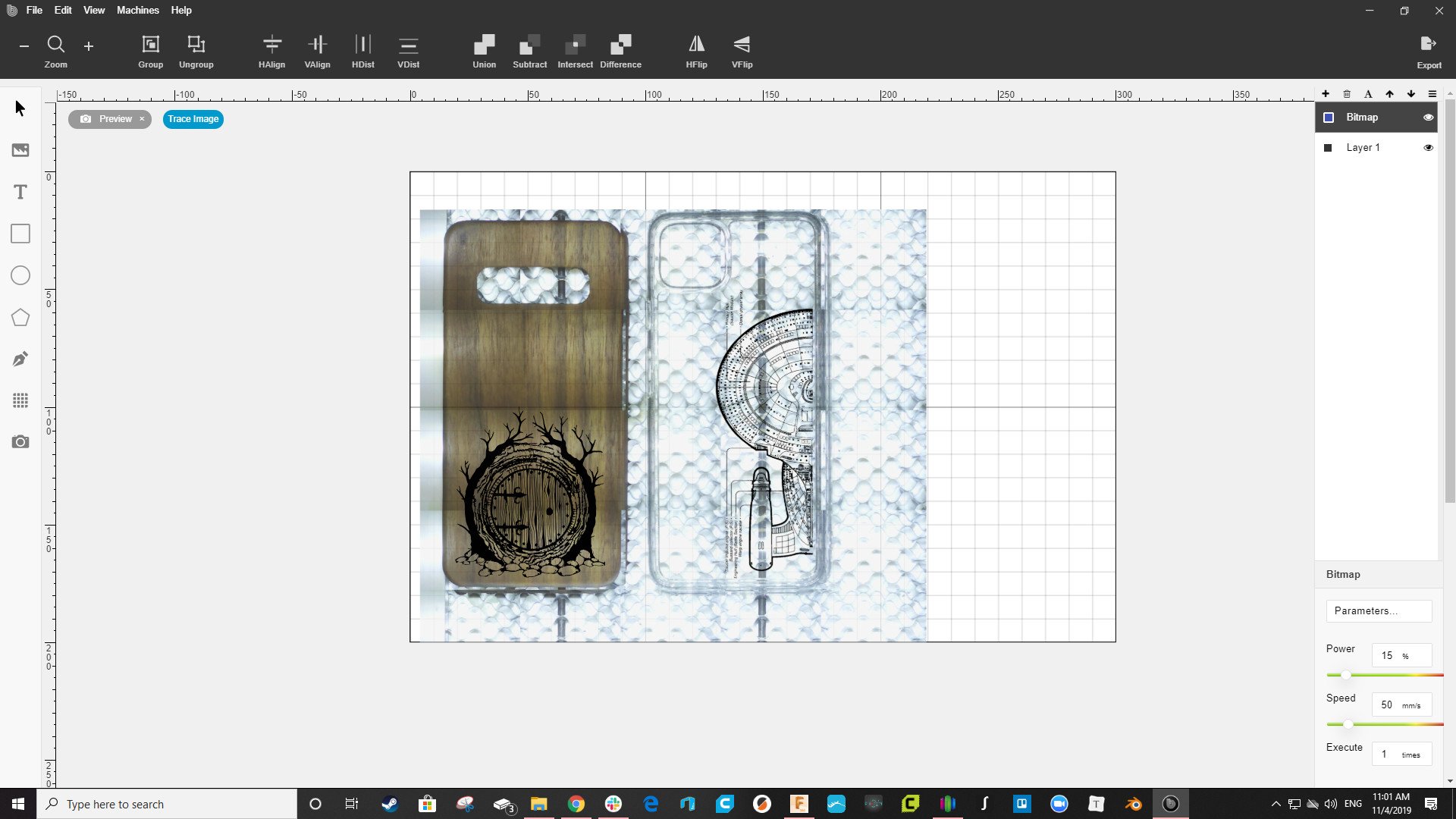

While the Beam Studio software is ok, it isn't anything that blows me away. The interface is simple enough, and while the camera is relatively low resolution, it works to show your material on the screen so you can align everything correctly.

I would like the ability to create voids in the artwork, though. I wanted to put a map of middle earth across my Macbook Pro but didn't want to cut through the Apple logo. The program needs to allow me to create a circular "hole" in the image that will make the laser skip that section.

I feel like there could be more to the Studio to help you make the most of Beamo, but the software is early, and the team at FLUX are working hard on a mobile app called Beamcam that will allow you to take pictures of your artwork and print them directly from the Beamo. This is going to add a tremendous amount of variety to the things you can create.

This is all just splitting hairs, though, as the Studio does what you need it to do, and it has yet to make any of my cuts fail. The Studio also tells me how long the cut will take and has a little pop-up that keeps you abreast of what's happening in the machine.

Should you buy the FLUX Beamo?

As of the writing of this article, the Kickstarter campaign is at $314,487, which blows past its funding goal of just $25,000 and now I have spent the last three weeks with the Beamo I can say those backers aren't going to be disappointed. With the Kickstarter offering the Beamo at a significant reduction, now is the perfect time to get on board.

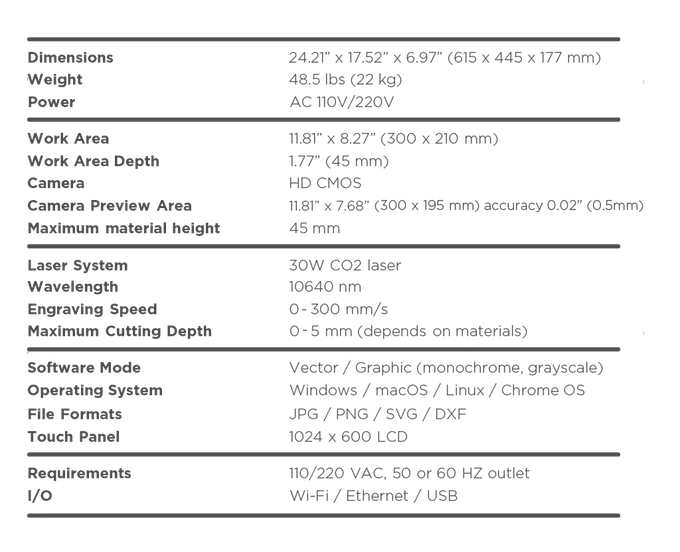

Even at the recommended retail price of $1,499, the Beamo is less than half the cost of its competitors and while it doesn't offer all of the features that they have, it offers more than enough to make that price point a bargain.

I have enjoyed my time with the Beamo and will continue to push the boundaries of what the machine can do. If you are a maker who loves the creation process, a teacher who wants to bring something new to their class, or a budding entrepreneur looking to make a business, the Beamo is the right choice for you.

James is a Former Contributor who built his first PC when he was 13 and has never looked back. He can be found on Windows Central, usually in the corner where all the 3D printers are, or huddled around the Xbox playing the latest games.