When Anycubic said they would be releasing a slew of new MSLA printers that use monochrome LCDs, I had assumed they'd take older models, swap the screen, and then call it a day, but I was wrong. The Photon Mono is one of three new printers from Anycubic, the Mono SE, Mono, and the Mono X. The big changes are the monochrome LCDs, which allow for much faster layer times of under 2 seconds and a longer lifespan than RGB counterparts. Resin 3D printing is about to go through a major change, and Anycubic is embracing it in a big way.

Bottom line: Anycubic has released a resin printer which has no serious defects, isn't a pain to use and has a very easy to use slicer with preconfigured profiles for its own printers, holding your hand all the way.

For

- Great detail, even at 0.15mm layers

- Speedy, >2 second layer times

- Almost no odor when printing

- Touch UI is simple to navigate

Against

- Relatively small build volume coming from FDM

- Photon Workshop slicer routinely craps the bed

- Touchscreen is tiny with terrible viewing angles

Anycubic Photon Mono: What I like

The Anycubic Photon was one of the first consumer-grade LCD based resin printers, coming out in 2018. For an asking price of $500, it was a fraction of the Peopoly Moai's price, and the Formlabs machines were so much more expensive, it was best not to contemplate them. People expected the quality to take a significant drop from the Laser-based SLA machines, but we were wrong.

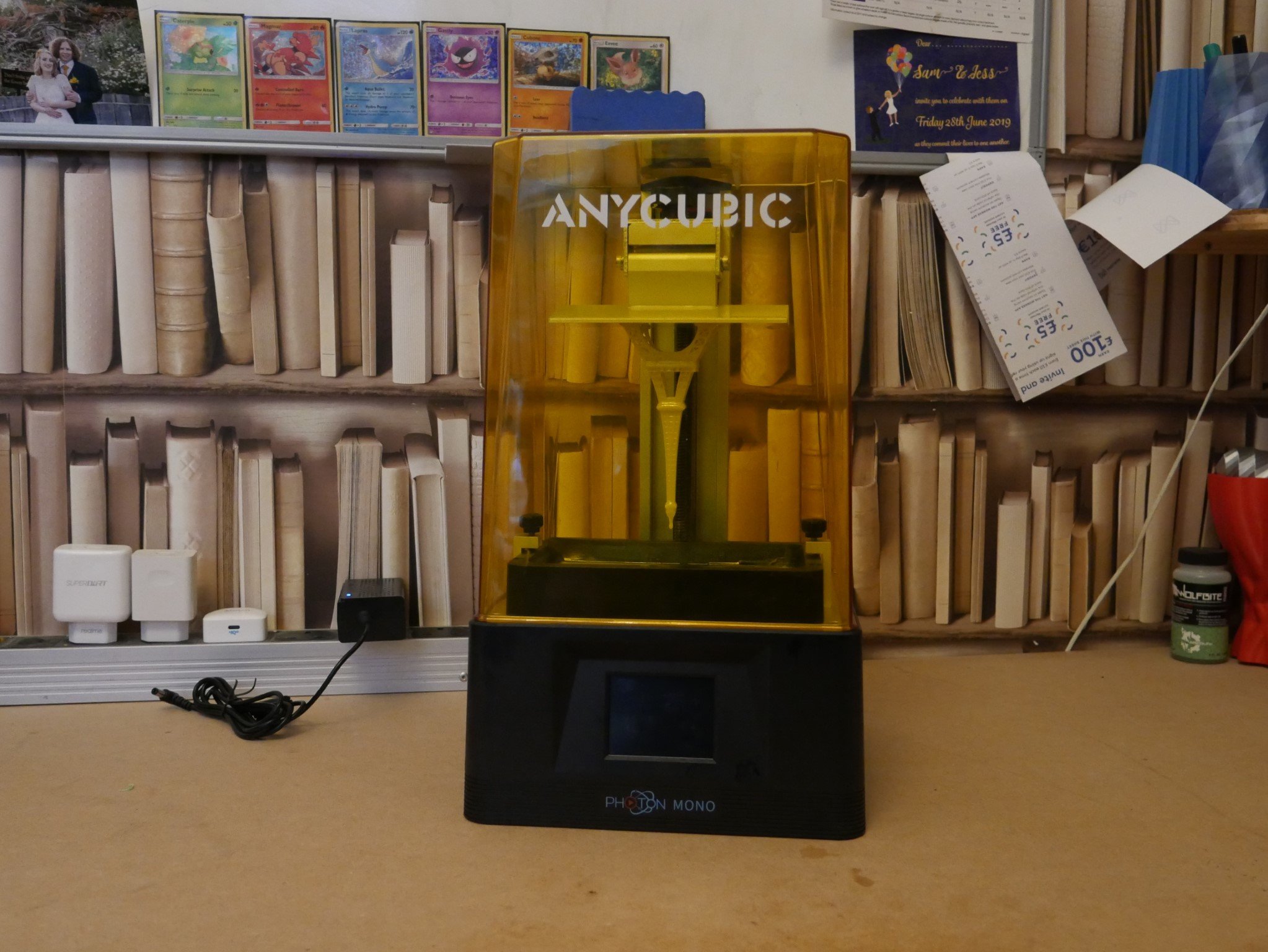

The Photon Mono's design is excellent, and I'm a big fan of the shape and lines.

The Photon Mono's design is excellent, and I'm a big fan of the shape and lines. The large black base is injection molded with a geometric pattern cut in the front for the touchscreen to sit angled up at the user. On the left is a ventilation grille/air intake with a triangle pattern, but the rear pattern is a more dense hexagon grid. On the right-hand side, we get the power switch and the USB port, I would have preferred these closer to the front on the right, but at least they aren't on the rear. Sitting atop this base is the yellow/orange UV protection lid, which is completely removable, unlike the hinged lid of the original Photon. This lid stops the resin from curing when it's not meant to, and it also protects your eyes from the UV light from the printer.

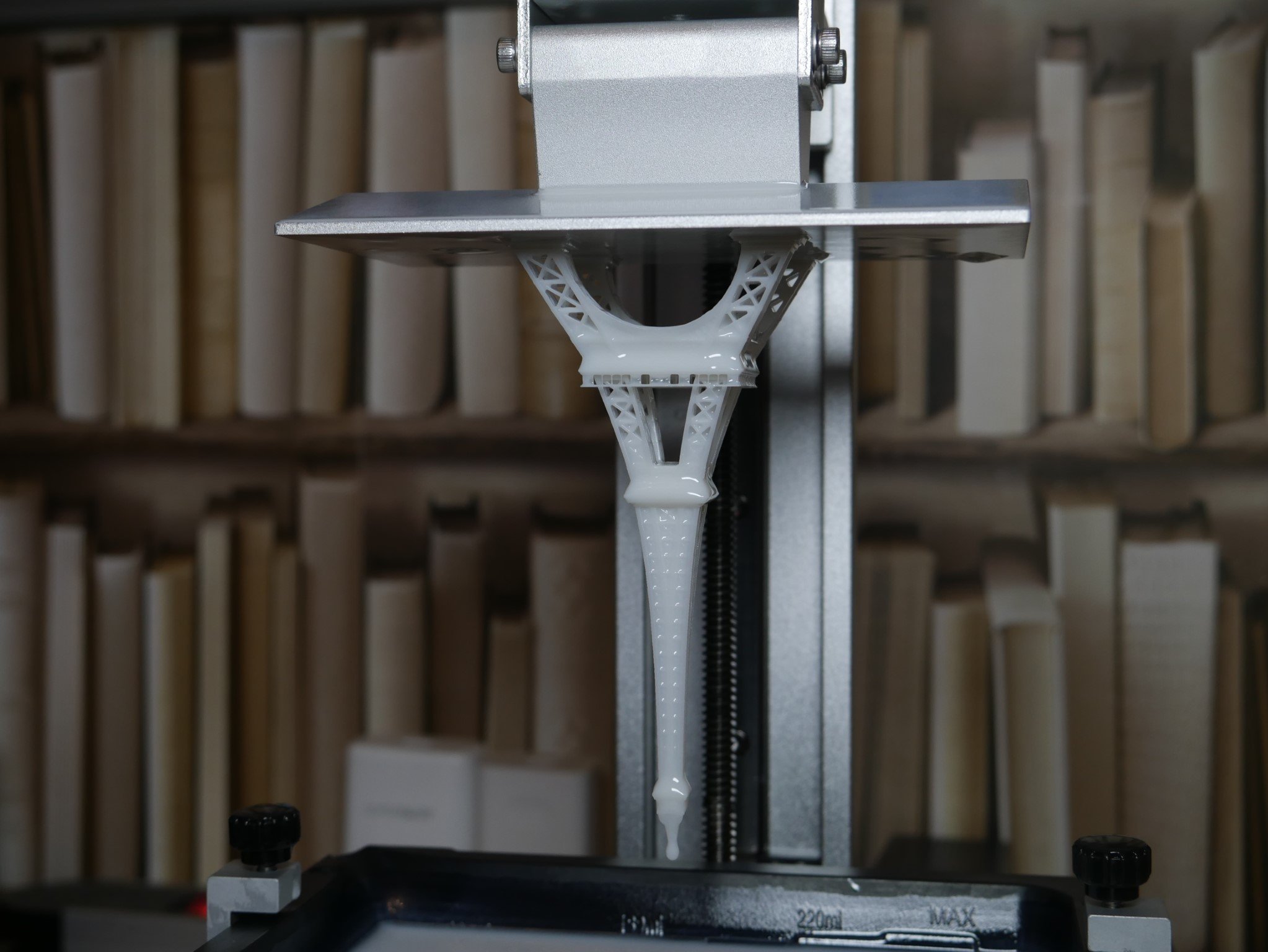

Mechanically, resin printers are a lot simpler than FDM machines; instead of an X, Y, Z, and Extruder motor, we have one; the Z motor. The printer lowers the build plate into the resin vat, and after each layer is cured, lifts it to cure the next one. Because of the way LCD based printers work, instead of drawing the outline with a laser, the screen displays the image to cure, and the entire build plate is cured at the same time, meaning if you have one model or 5 models, as long as they're the same height they'll have identical print times.

The Photon Mono when printing is pretty quiet and has almost no smell. You will hear the Z motor when the layer changes, but it is more of a low-medium frequency hum than anything shrill. And unlike other resin printers, the fans to cool the UV LED and extract fumes aren't annoying or overbearing here; in fact, I've been in the same room as the printer after it's finished printing, and I forgot it was even on, something that can't be said for all MSLA printers.

So about the prints, they're awesome. Resin printing is, for the most part, a lot smaller than FDM printing, with a build area of 130x80x165mm I can fit almost 2.5 of these full build volumes on my FDM printer with a 235x235x250 build volume, but the trade-off you make for small build volume is ridiculous detail and accuracy. Whereas an FDM with a 0.4mm nozzle will print a 0.4mm line and have, at best (most times) a 0.1mm layer height, on LCD resin printers, the recommended layer height is 0.05mm, and on the Photon Mono's LCD, the line width is also 0.05mm so each line can be 8 times finer, leading to the cool busts, minis, and props you see here.

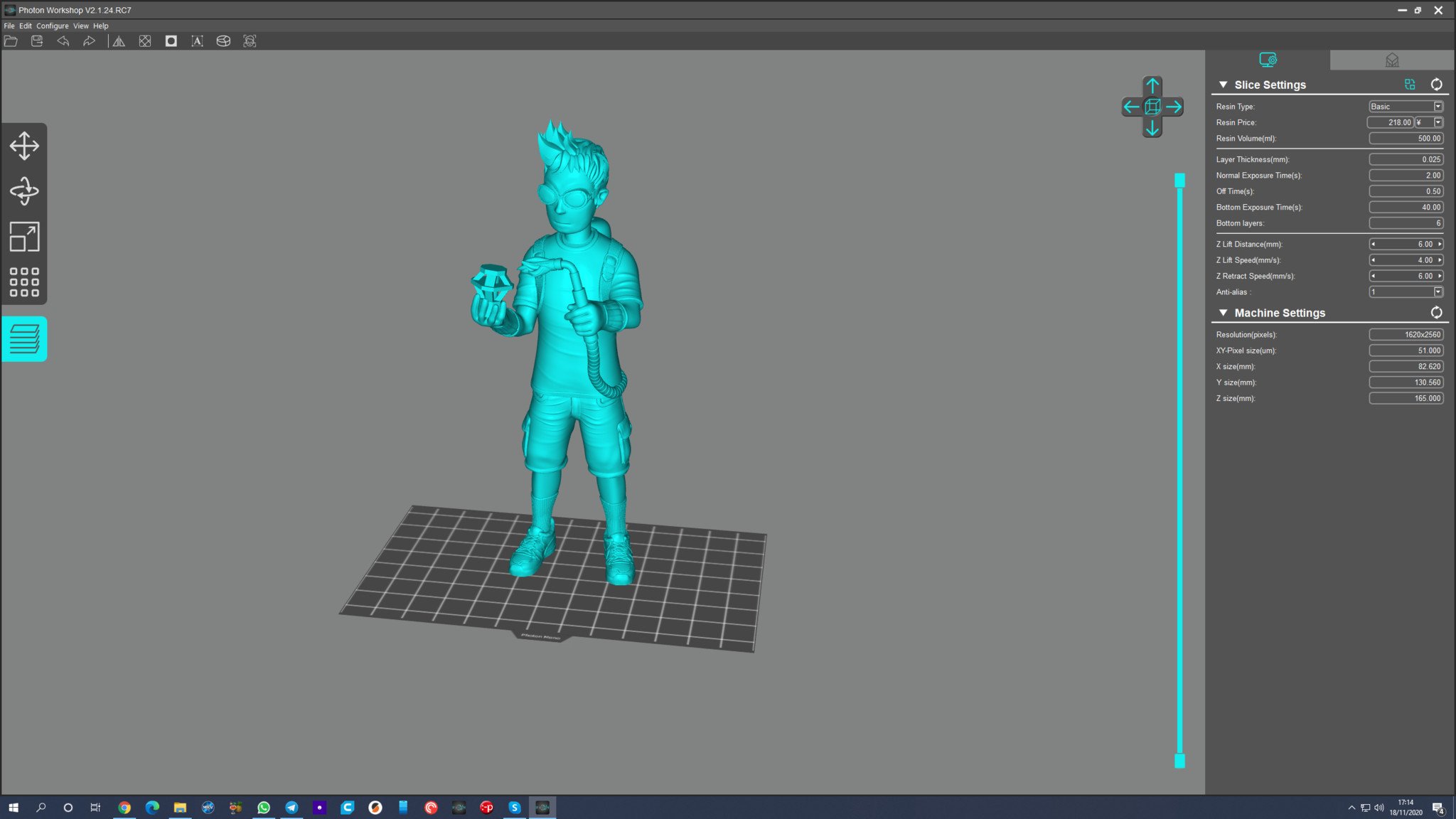

I also need to give Anycubic props for their slicer when it works. Slicing 3D files for resin printing is still harder than it is for FDM prints, but that is likely because it is a lot newer consumer process, but Photon Workshop is very easy to use. It has presets for Anycubic printers, but you can create profiles for any resin printer you like. Drop the file on the build plate, rotate, scale, and move to your heart's content; then, you change layer height with the second tab going to support on the right-hand side. I don't think Supports are quite as easy as Chitubox, but as of writing this, Chitubox doesn't support the Photon Mono's file format.

Anycubic Photon Mono: What I don't like

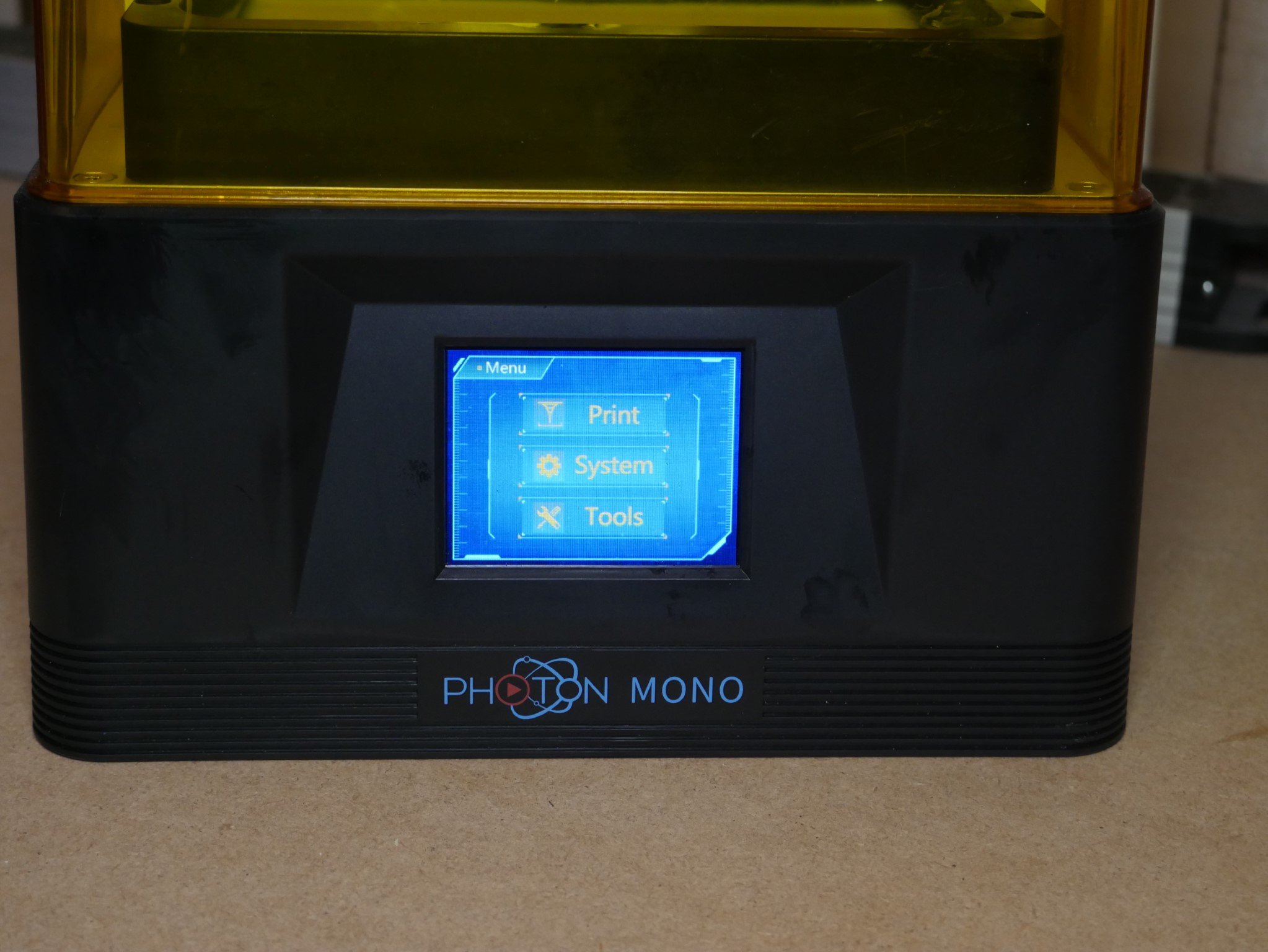

Outside of resin printing's normal cons, such as the smell, the smaller build volume, and the price of materials, a few things are Photon Mono specific that I don't like. Starting with the touchscreen on the front. Whilst the touchscreen is a very nice addition, and the user interface is better than some of the other resin printers I've seen, it is a tiny 2.8" TN screen with truly horrible off-axis viewing capabilities. I'm not asking for a Formlabs Form 3 level screen or even the Prusa SL1 touchscreen, but something better than this, please.

Another issue I've come across is with Photon Workshop, which routinely fails when there is too much going on on the platter. I initially thought this was my computer, I tested it on 2 laptops and another desktop, but they did the same. The issues range from supports disappearing, drain holes just deciding they'll go somewhere other than where you placed them, and my least favorite, crashing when slicing a heavy model, and you have to start from scratch again.

The competition

In the $200-$300 MSLA resin printer space, there are a fair few options. The most prominent player is Elegoo with their Mars line of printers, recently updated to the Mars 2 Pro Mono, with the same Monochrome screen as the Photon Mono. Still, a slightly smaller footprint, the kicker here is that it's also $40 more expensive, coming in at $300 on Amazon, and you don't have a custom-tailored slicer for the Mars. Still, it does have a pre-configured slicer profile inside the very popular and very capable ChiTuBox.

Next would be the Phrozen Sonic Mini , at $199, it's $60 cheaper than the Photon Mono, which still has the Monochrome screen for fast cure times and a longer lifespan. However its a smaller 5.5" 1920x1080 screen, so the build volume shrinks to 120x68x130mm that's a fair bit smaller than the 130x80x165 of the Photon Mono and the 130x80x160 of the Mars 2 Pro, but also the lower 1080p resolution means the XY pixel size is larger than on the other printers. The Phrozen Sonic Mini also uses ChiTuBox as it's slicer software.

Lastly would be the older Anycubic Photon S. it's a 5.5" 2560x1440 screen, so it'd have a 115x65x155mm build volume, similar to the Phrozen Sonic Mini. Still, because the resolution is higher, you get a better XY pixel density. Sadly, being an older machine, this is an RGB screen, so instead of the sub-2-second layer cure times, it's now 10-14 seconds per layer, significantly increasing print times, but also RGB screens have a limited lifespan of 500 hours, roughly, whereas monochrome screens last well over 2000 hours. The Photon S can be had for around $289 on Amazon.

Anycubic Photon Mono: Should you buy

So should you purchase the Photon Mono? I think it's a pretty great deal at $270, and no hardware related dealbreakers are here. In the month I've been testing the Photon Mono, I was printing almost every day, I don't have a concrete number, but I've put over 100 hours of printing and 2 liters of Resin through this machine with the only failed prints being my fault.

If you want a resin printer and are fully aware of what that entails, then $270 for the Photon Mono and $150 for the Anycubic Wash and Cure station is a great investment. Its small footprint doesn't take up that much room, it's quiet, it's repeatable and reliable, and Anycubic has been at this long enough to fix Photon Workshop quickly. Hopefully, the touchscreen is the next upgrade.