Windows Central Verdict

At just $209, or $189 if you got in the early bird offer, Anycubic's Kobra Go is a stellar entry point to 3D printing, however, their lax approach to software licensing is going to make upgrades harder, and is losing them goodwill in the community.

Pros

- +

+ LeviQ automatic bed levelling makes getting started easy

- +

+ Belt tensioners

- +

+ Standard Nozzle sizes

- +

+ USB-C for connecting to host devices

Cons

- -

Flex plates are slightly smaller than standard sizes

- -

the screen is a little small

- -

Textured PEI doesn't adhere well to PLA

Why you can trust Windows Central

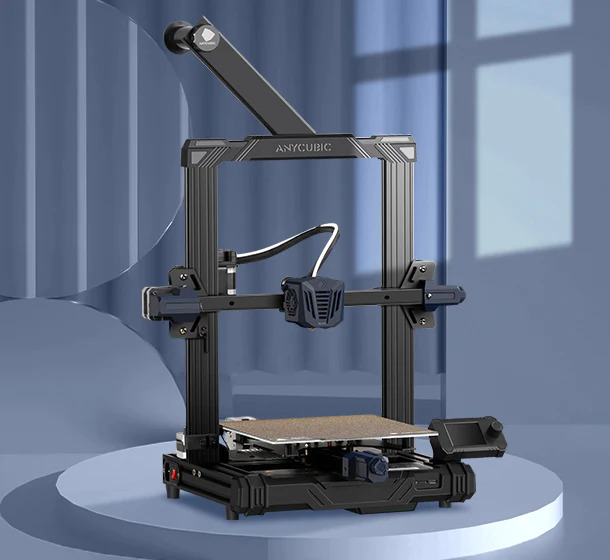

To say that Anycubic is prolific in bringing new 3D Printers to market would be an understatement, in the last year Anycubic has released the Vyper, Kobra Max, Kobra Plus, Kobra and now the Kobra Go, those are just their FDM printers, let alone the resin printers. So why should you care about their newest printer, the Kobra Go? well Anycubic has decided to bring some features of more expensive printers.

What are those features then? well it is automatic bed levelling, called LeviQ, and a magnetic spring steel sheet with textured PEI on it for print adhesion. Printers at the sub $200 price point often have spring mounted beds with four adjustment screws you have to screw or unscrew to get the perfect distance between the nozzle and the bed. They also often have print surfaces that are stuck down permanently, or use weak floppy fridge magnet type beds. These two changes often can add up to $100 on the printer price.

Anycubic gets around this by simply assembling less of the printer themselves. assembly time in the factory adds extra cost, so if they assemble it less and show you how to assemble it, they can give you more features for the same price as the less feature rich printer, something I am a fan of.

Pricing and availability

The most important thing about the Kobra Go is the price, at $209 retail, but $189 for the first 1000 early birds is quite inexpensive. It might not be as cheap as the Neptune 2 was at $160, but this is also likely to be available in a reasonable timeframe, unlike the first 6 months of the Neptune 2 release. The Kobra Go is also available on Amazon for $219 if you have Amazon Prime, but if you don't it is a whopping $279.

On the Anycubic website, you can buy the Kobra go with the option of no filament, 1KG of PLA, 2KG of PLA or 3KG of PLA. Whilst that is nice, the cost of these filaments are not worth it for the quality, I would go to Printed Solid and pick up some Jessie PLA for $20 a kilo.

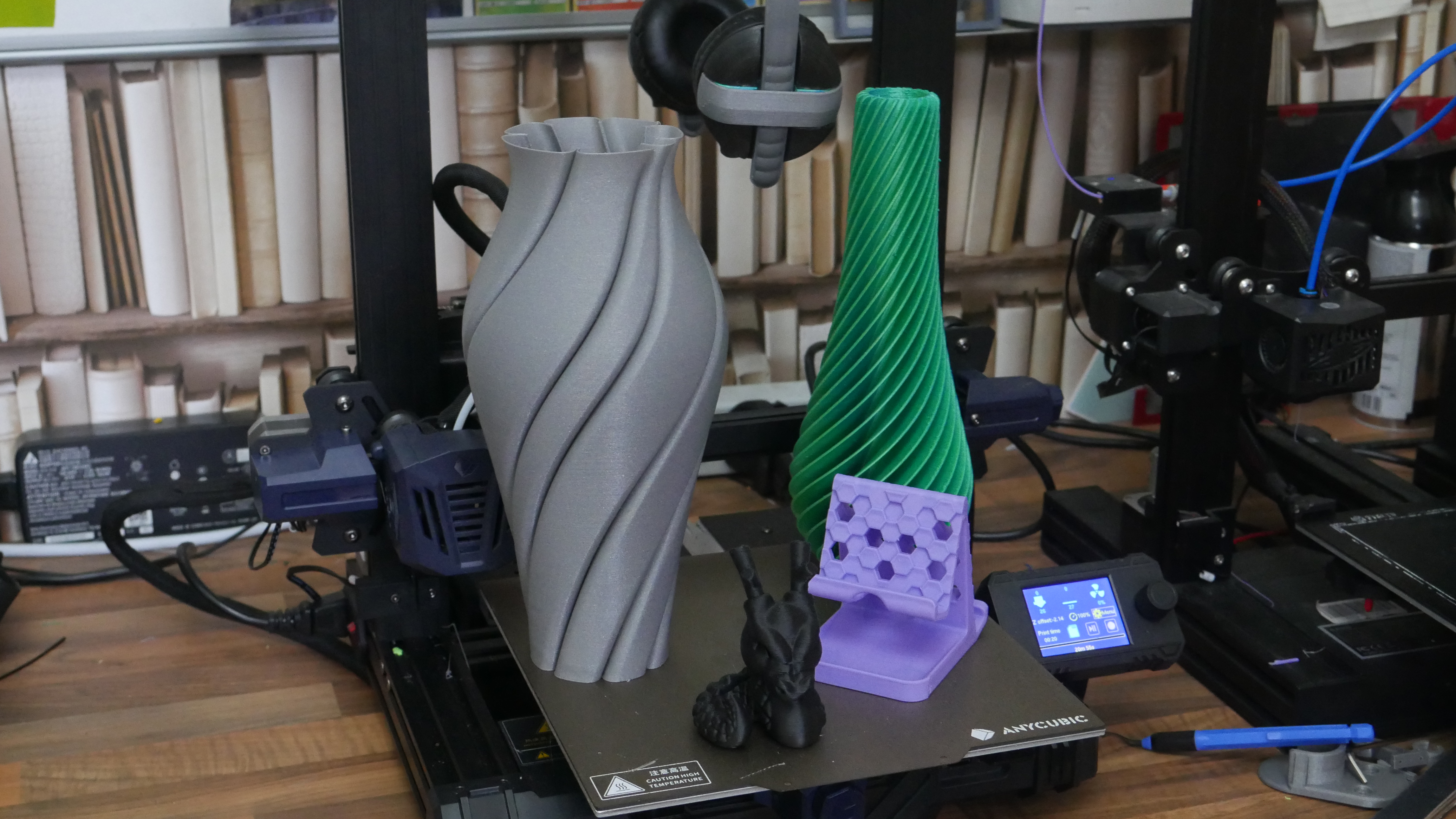

What you'll like

Whilst the inexpensive price is the reason people are going to be drawn to the Kobra Go initially, there is a lot to like. As someone who has spent countless time with a spatula and a hammer trying to get a print off of the print bed, only to break the model, the bed or both, the inclusion of a flex plate here is something to applaud. It is not a flimsy fridge magnet style bed, this is a piece of spring steel with texture PEI on one side and a clean underside, meaning if you wish to, a sheet of smooth PEI or maybe even BuildTak on the rear could make PLA printing more enjoyable and also give a smooth finish.

The other is bed levelling. For people just getting into 3D printing, there are a few things as important as your first layer. On most inexpensive FDM 3D printers you set this height between the nozzle and the bed by 4 screws, one in each corner of the bed, you move the nozzle to each corner, loosen or tighten the screw to get the nozzle to barely touch the bed, many people use a sheet of paper as it is a consistent thickness. The problem with doing this is, if you adjust the front left corner first, and then do the other three, the relative position of that first corner has changed, so in actuality, you are going around doing this 3 or so times. even then it might not bed perfect and you adjust on the fly.

The Kobra Go, however, has an inductive levelling probe next to the hotend. the bed is fixed, there are no springs and there are no screws. The printer when told to do an auto-level brings the head down until the sensor senses the bed and moves to the next point, and in software, you tell the printer when the nozzle is at zero, the correct printing height. This is not as simple as the Kobra Plus or Kobra Max whose entire hotend is the sensor, you do not need to worry about telling it where zero is, as the nozzle is able to tell, but those are significantly more expensive. Taking the pain out of getting the first layer down right allows you to get printing sooner, and the flex plate allows you to remove the bed without ruining that bed level.

Something that is quite nice after using the Anycubic touchscreens for a while is the return to an LCD screen and a rotary encoder, whilst I would still prefer it to be a bit larger, I find the options on here much easier to understand and quicker for adjusting things like temperature, bed offset and fan speed. like I said, at 2.4" it is pretty small, however the actual quality of the screen is fantastic, good viewing angles, nice colours and quite bright, kudos to Anycubic here.

The Kobra Go also makes the switch to USB-C for it's host connection port. It's a small thing, but USB-B takes up a large amount of board space, and it's just a large clunky port, with phones, tablets, game consoles etc all switching to USB-C, it makes sense for 3D Printer manufacturers to adopt this, we all have USB-C cables lying about, but few still have a USB-B cable these days.

| Specs | Anycubic Kobra Go |

| Print Volume | 220mm x 220mm x 250mm |

| Print Surface | Textured PEI on a magnetic spring steel sheet |

| Extruder | Single drive gear, no gear reduction, plastic |

| Hotend | PTFE lined "mk8" hotend |

| Nozzle Diameter | 0.4mm Brass V6 style |

| Interface | 2.4" LCD with control wheel, USB-C, MicroSD |

What you wont like

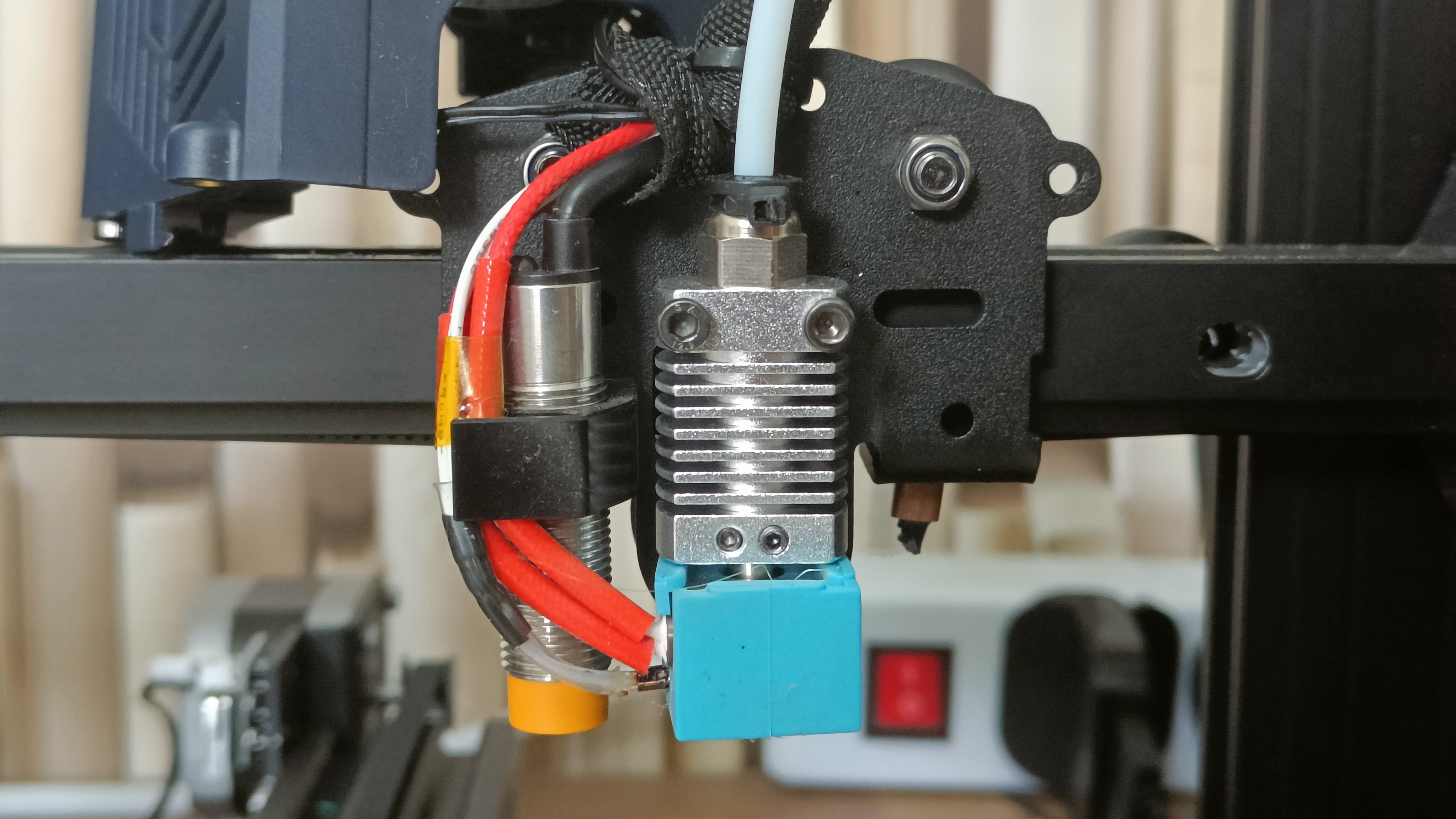

It's not all sunshine and rainbows here though, this is still a budget printer, and whilst they were able to give some higher-end features, it still has to give somewhere. Starting with the extruder, This is the cheapest extruder you can buy, it is injection moulded plastic, with a spring-loaded idler that houses a bearing, and the filament is driven by a spur, not even a proper drive gear. There is no tension adjustment, this gear will wear out quite quickly and it is going to be nigh on impossible to print flexible filaments through this.

Next up would be the hotend. This is another "as inexpensive as they come" product, this is a PTFE lined MK8 style hotend as you see in Creality printers, however, the surface finish on the heatsink is terrible, it looks like it has been cast but not milled, once again to save on cost. These are low-quality pneumatic couplers, which is why they are using zip ties to keep tension on them, and lastly, this is a PTFE lined hotend, which limits you to about 240c in temperature before it starts to degrade.

Something that almost no company tells you though is that PTFE tubing is a consumable, it does wear down and will need to be replaced. If you print at 250c for 8 hours you'll wreck it obviously, but even 215c for a years worth of printing will degrade it to the same point. All-metal or bimetallic heatbreaks that fit this style of printer are inexpensive and would be the first thing I personally would swap. An E3D Revo-CR, whilst pricey, would also make a lovely addition to this printer.

UPDATE 23/11/22: Anycubic have since released their compiled and uncompiled versions of Marlin, complying with that license. The review also erroneously stated that Anycubic had removed other printers from their Cura install, this was false and the license is therefore still intact.

Lastly is probably the most annoying downside because it is entirely preventable. A large portion of 3D printing is now possible because of expired patents as well as open-source hardware and software. The firmware used by Anycubic is called Marlin, Marlin is released under the GPL V3.0 license and freely available on Github. Whilst you don't need to know the entirety of the GPL Licenses, the important bits are that Marlin is free to use and modify as well as ship on consumer printers, all they ask you to do is share your modified code, both uncompiled, and compiled. This is a simple and reasonable request I feel but Anycubic is not adhering to this, in fact, they haven't done it for any of the Kobra printers.

This also moves on to the slicer they ship, a modified version of Cura. Cura, a slicer developed by Ultimaker is free and open source, available under the LGPL V3.0 license and available on GitHub, which is broadly the same as the GPL V3.0 license that Marlin is under. Anycubic removes other printers from the drop-down and adds their own printers into it and ships a compiled version to consumers usually on the SD card of the printer and as a download on their website, this is against the rules of the license.

Anycubic is far from the only company to do this, but without bringing it to their attention they are unlikely to change, and what makes this so annoying is the fact they have the uncompiled and the compiled modified code on their computers, they also have file hosting on their site, they are actively choosing not to host this for whatever reason, and it makes me mad that Scott and the rest of the marlin team are getting effectively ripped off because of it.

Competition

This is where it gets a bit harder for the Kobra Go because there are a lot of printers that have this build volume or are roughly this price. The first competitor is from Creality, the company who originally made this style of printer with this build volume etc. The Creality Neo line-up is modern updates to some of Creality's most popular printers. The Ender 3 Neo here is $219 and has the same 220x220x250mm build volume, it now has a Creality CR-Touch automatic bed levelling probe, whilst retaining the bed springs. There is a single gear spur extruder except this is made of metal. Lastly, the bed is a sheet of borosilicate glass with a silicon carbide coating. However the Ender 3 Neo still has a PTFE lined hotend, a larger but much lower resolution monochrome screen, and not to forget you have to build the Ender 3 Neo just like the Kobra Go.

Elegoo has a competitor to the Kobra Go as well, in the Neptune 3. The Neptune has a slightly larger build volume of 220x220x280mm, It has a metal dual gear extruder, a filament run-out sensor and a removable 4.3" touch screen. All of this is for $209 currently, with a soon price raise to potentially $300. The Kobra Go is going to struggle to compete with the current crop of budget printers if they aren't careful.

Should you buy it?

You should buy this if ...

- You want an easy entry to 3D Printing

- You don't mind the assembly

- User experience matters more than license compliance

You shouldn't buy this if ...

- You care about software licensing and sticking to it

- you want to be able to modify your printer

Anycubic has done a pretty good job at making an inexpensive printer not absolutely suck. The first few generations of cheap printers, including the original Ender 3, made many compromises to get to their low prices, they were loud, they had thin weak springs for the bed, they had thin warped aluminium beds, and much more. The Kobra go is mostly quiet, it's got a flat bed, with auto bed levelling, a removable print surface and some forward-looking features like the USB-C host port and the higher resolution LCD screen for things like Gcode previews in the future.

The Kobra Go is a competitive printer in its normal price point, but if Anycubic is able to bring it down to the $189 or $199 always, I think that'd help it gain users. I just really hope that Anycubic takes the open source licenses seriously. No one loses out when they abide by the license, and it makes upgrading and modifying your printer, the thing you own, much easier, let alone helping out the developers that are creating the software you're benefiting from.